Particle generator | ||

| ||

ProductsAbaqus/ExplicitAbaqus/Viewer

Introduction

The particle generator capability enables a modeling approach in which the discrete element method considers particles only after entering a region of interest. This approach can simplify model set-up and improve computational efficiency. Characteristics of this capability include:

-

particles are generated at an inlet that can vary in shape over time,

-

generated particles can have random sizes based on a user-specified probability density function,

-

multiple species of particles can be generated simultaneously by a single generator, and

-

the net mass flow rate and particle speeds at the inlet can be specified with time dependence.

![]()

Applications

How you use the particle generator will depend on the process being analyzed. Two broad usage categories are as follows:

- Model creation

-

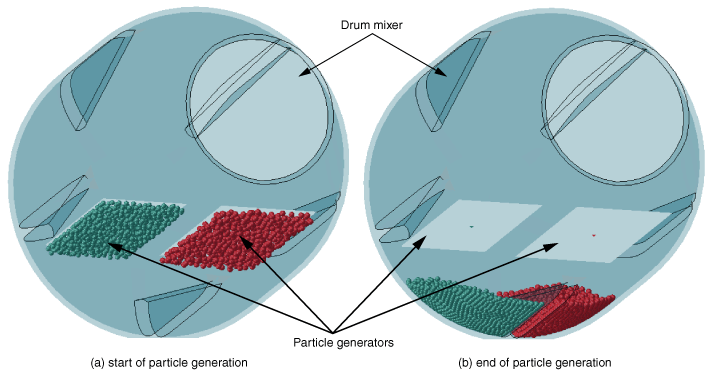

In many applications the particle generator can be used to fill part of a domain with particles to establish initial conditions for subsequent studies. Figure 1 shows an example where two particle generators are filling a drum mixer with two different batches of particles prior to performing a mixing simulation. The sequence of images show the start and end of the particle generation phase.

Figure 1. Model creation using particle generator.

- Continuous generation

-

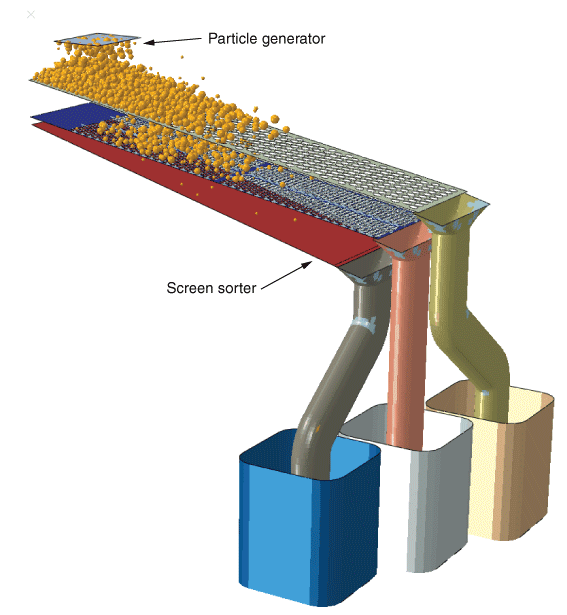

In another type of application a particle generator can be used to inject a continuous stream of particles into the domain while an event of interest involving particles that have been introduced is underway. Figure 2 shows the use of a particle generator in a sorting analysis. In this application a particle generator is continuously feeding random sized particles to a screen sorter assembly while the analysis is in progress.

Figure 2. Continuous particle generation example.

![]()

Defining a particle generator

To define a particle generator, you specify a name for the generator, the type of particle to be generated (only PD3D elements are supported), and the maximum number of particles that may be generated during the analysis. You must define an inlet surface, the list of particle species that will be generated, and the size distribution for each species.

In many processes the number and speed of the particles being introduced into the domain are not constant during the analysis. You must define the time-dependent mass flow rate per unit inlet area and the particle speed at the generator inlet to control the rate of injection of particles of each species through the inlet. These specifications allow the possibility of turning the particle generator on or off during the analysis.

Input File Usage

PARTICLE GENERATOR, NAME=generator_name, TYPE=PD3D, MAXIMUM NUMBER OF PARTICLES=number

Inlet surface

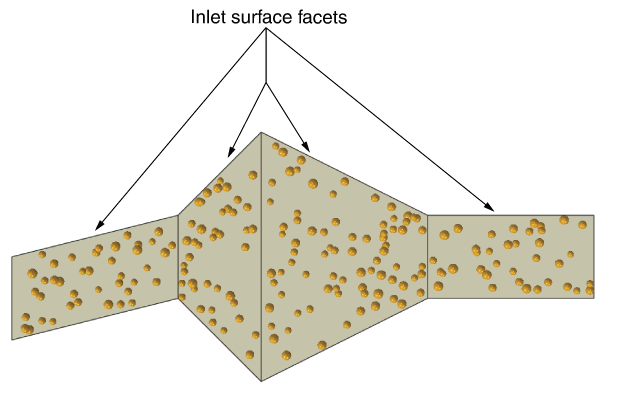

The inlet surface can be thought of as an opening through which the particles are injected into the domain. It is important that no other model feature is positioned in front of the generator inlet to obstruct the flow of particles. An element-based surface must be defined for the inlet surface. Using surface elements is appropriate in most applications. Care should be taken with respect to the positive surface normal direction at the inlet because the initial particle velocity will be in this direction. A complex inlet geometry as shown in Figure 3 may have several facets. In this example the normal direction to the inlet surface is out of the page.

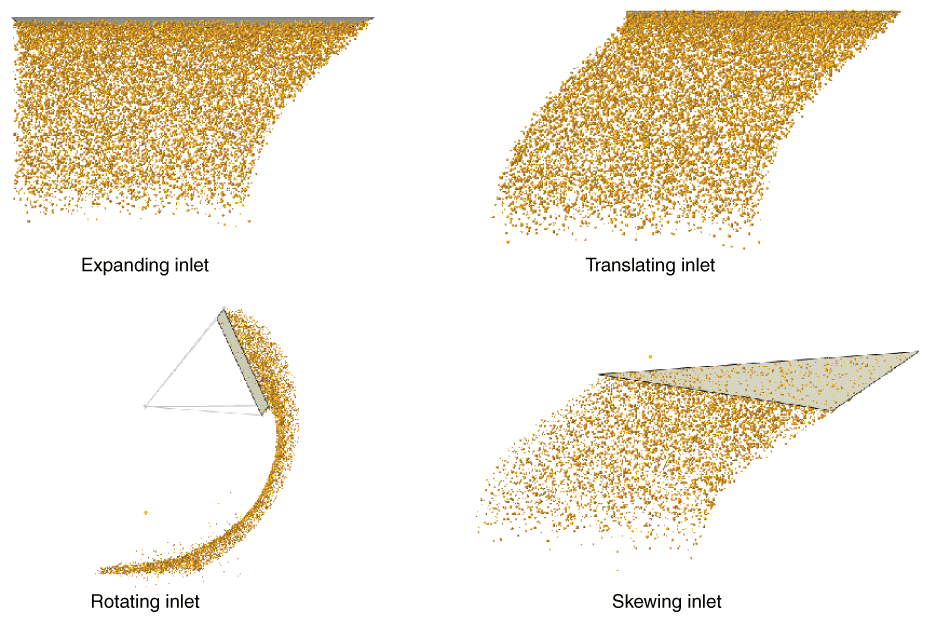

The size and shape of the inlet surface can be modified during an analysis by adjusting the nodal positions of the inlet surface. The inlet surface can expand, collapse, and translate as well as undergo rigid body motions. Figure 4 shows the inlet surface of four different generators being subjected to different deformation and motion.

Input File Usage

PARTICLE GENERATOR INLET, SURFACE=inlet_surface_name

Particle species

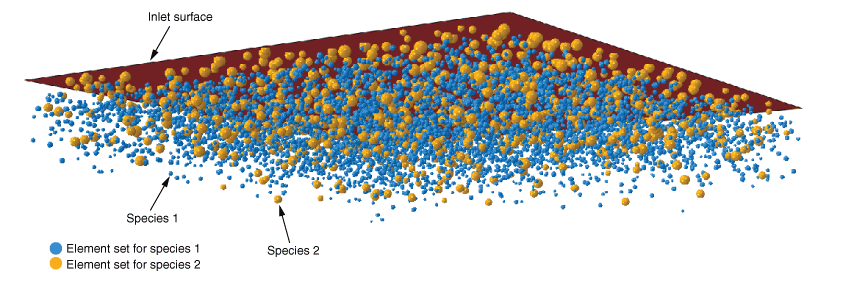

In many applications several different types of particles interact with each other. For example, sand, cement, and aggregate particles are mixed together to prepare a batch of concrete. A particle generator can be used to generate one or more species of particles as shown in Figure 5, where the two colors represent the two species of particles that have been simultaneously generated by a particle generator. An element set name is associated with each species in the mixture. This is analogous to a regular DEM analysis where the particles are grouped into element sets.

Input File Usage

PARTICLE GENERATOR MIXTURE element set for species 1, element set for species 2, etc.

Particle size distribution

Statistical distributions are commonly used to specify the particle sizes. Statistical distributions are defined by analytical or user-specified piecewise linear tabular probability density functions (PDF). The particle generator supports the following different types of probability density functions: uniform, normal, log-normal, and piecewise linear. The normal and log-normal PDFs have well-known analytical forms that depend on the mean and standard deviation of the random deviate. In some cases the particle size distribution may be obtained from sieving particle samples in the field. These data are usually in the form of a table of size ranges and the percentages of particles that fall within those size ranges (a histogram). The piecewise linear PDF can be used for such data. See Probability density function for further details on the usage of probability density functions.

Mass flow rate

The rate of generation of particles is governed by the specified mass flow rate per unit area at the inlet, the area of the inlet, and the ability of the generator to insert a particle of a given size. The time varying mass flow rate per unit inlet area, , has the units . For a multiple species particle generator the total mass flow rate per unit inlet area is the sum of the mass flow rates per unit inlet area of the individual species:

The time varying mass flow rate per unit inlet area for each species must be provided in the form of an amplitude table (Amplitude Curves).

Input File Usage

PARTICLE GENERATOR FLOW, GENERATOR=generator_name , mass flow rate amplitude for species 1, mass flow rate amplitude for species 2, etc.

Particle speed

For a given particle generator, particles of all species are introduced into the domain through the inlet with a specified flow speed. The flow direction of the particles is along the normal to the inlet facet. Particles generated from different facets in the inlet surface will all have the same flow speed; however, depending on the facet normal direction, they may have different velocities. The time varying particle flow speed must be provided in the form of an amplitude table (Amplitude Curves).

Input File Usage

PARTICLE GENERATOR FLOW, GENERATOR=generator_name flow speed amplitude curve,

![]()

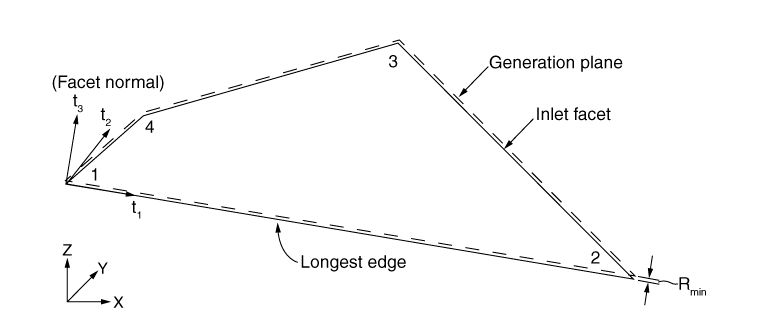

Local coordinate system for inlet faces

The current coordinates of the nodes of each facet in the inlet surface are used to define a plane (a generation plane) where particles will be generated. Figure 6 shows the local directions of the generation plane. The first local direction, , is defined by the longest facet edge, while , the third local direction, is normal to the facet. The normal to the facet is obtained from the cross-product of the diagonal vectors (the vector joining nodes 2 and 4 and the vector joining nodes 1 and 3; see Figure 6 for local node numbers). The second in-plane direction is . The plane of generation is positioned in front of the inlet facet, where is the smallest particle radius for the generator.

The in-plane particle coordinates of a particle are generated randomly according to a uniform random distribution. The generated in-plane coordinates are acceptable if the particle can be placed at that location ensuring that it does not overlap with previously generated particles and also does not intersect the boundaries defined by the facet edges.

![]()

Assigning properties to particles

Particles of different species will have different size distribution, density, and contact properties. To assign a density and size distribution for a particle species, the corresponding element set name is specified on a section definition for the PD3D elements. The element set name is also used to define a surface that is referred to under the contact specifications. This way of assigning particle properties and contact properties for generated particles is no different from what is done for user-defined sets of discrete particles. See Discrete element method for details on how to assign properties to PD3D elements and how to set up contact definitions for a DEM analysis.

![]()

Particle size rejection

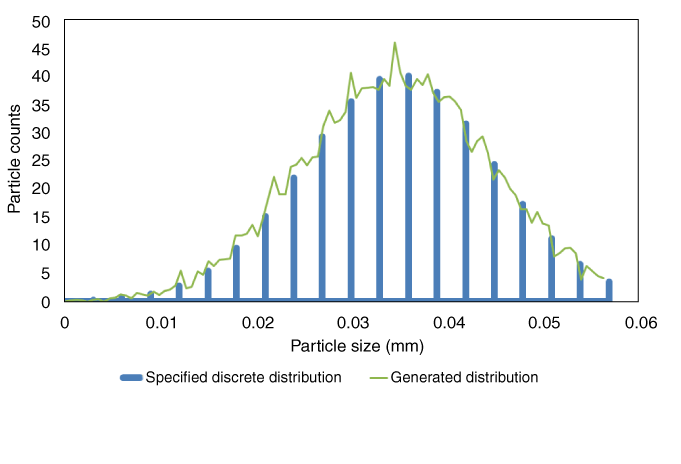

Abaqus/Explicit discards particle sizes that are outside the specified minimum and maximum range for the PDF. For normal and log-normal type PDFs this leads to a truncated distribution, as explained in Probability density function. Keep this in mind when comparing the generated particle size distribution to the target PDF.

A generated particle size is discarded if it is too large to fit through the current inlet geometry. It is possible that the generator may fail to place a particle in the randomly generated location in the generation plane if there is not sufficient room to accommodate the newly generated particle size. If this happens, the generator will generate another random location and attempt to place the particle there. By default, 15 such attempts will be made, after which the particle size is discarded and another particle size is randomly generated and the process is repeated. You can modify the default number of attempts to place a generated particle size.

If particle sizes are rejected because of either of the above reasons, the generated size distribution cannot be guaranteed to match the specified size distribution. Figure 7 shows a comparison of generated and specified piecewise linear particle size distributions for a specific problem where 14608 particles were generated at a constant mass flow rate and with constant particle speed through an inlet of fixed geometry. The overall agreement of the generated particle size distribution is good even though the generator was unable to insert some particles into the domain.

Input File Usage

PARTICLE GENERATOR, MAX INSERTION ATTEMPTS=number

![]()

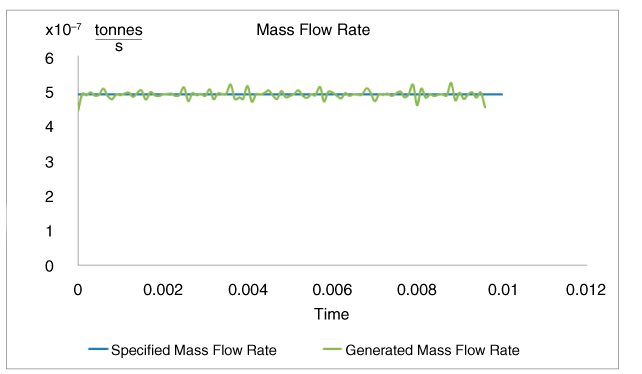

Mass balance for continuous generation

At any increment, k, corresponding to the end of increment time, , and time increment size, , the specified mass of particles of species, i, to be generated is

where is the current inlet facet area. Due to the discrete nature of the time increment and particle sizes, the particle generator will not be able to match the specified mass exactly for the species for the given increment. The particle generator, therefore, maintains a mass balance for each species. For a given species a negative mass balance indicates that for that species the mass of particles generated was higher than what was required. The excess mass balance for species, i, from the previous increment is taken into account while computing the target mass to be generated in the current increment:

The mass balance for species i for the current increment is

where is the actual mass of the particles generated in increment k. The particle generator tries to match the specified mass flow rate per unit inlet area as closely as possible. If the target mass for a species is negative because of a high negative mass balance, no particles will be generated for that species until the target mass becomes positive again. Figure 8 shows a comparison of generated and specified mass flow rate for a specific problem where the specified mass flow rate per unit inlet area does not vary with time and the inlet geometry is fixed.

![]()

Inlet blocking

The flow speed, , and mass flow rate per unit inlet area, , are related as follows:

where is the particle density and is the solid fraction. The solid fraction is the ratio of the volume of particles to the volume of the region they occupy. This relation suggests that the packing of particles ahead of the inlet increases for a given mass flow rate per unit inlet area as the flow speed is reduced. If this happens, the particle generator will take many more attempts to insert a particle. Therefore, a meaningful specification of flow speed for a given mass flow rate per unit inlet area is crucial for the efficiency of the particle generator. It is also important that no other model feature is positioned in front of the generator inlet to obstruct the flow of particles.

![]()

Automatic halting of particle generator

A particle generator will permanently halt after generating the maximum number of particles. Since it may be difficult to make an accurate estimation of the total number of particles that need to be generated during an analysis, overestimating the maximum number of particles will ensure that a particle generator will not run out of particles. However, grossly overestimating the maximum number of particles will lead to larger memory requirements for the analysis.

The particle generator will temporarily halt for an increment if the region near the inlet has a high volume fraction of particles. This helps avoid performance degradation due to an excessive number of failed attempts to insert a new particle when the inlet is becoming clogged with existing particles. The default threshold for a temporary halt to the generator is a particle volume fraction of 0.4 over a volume that extends in front of the inlet surface, where is the maximum particle radius for the generator. You can modify the default value of the solid fraction used for halting the generator.

It is possible that the current inlet geometry and the particle size distribution is such that the particle generator repeatedly exhausts the 15 attempts to insert a particle of a given size. If 10 such cycles of 15 attempts each have been unsuccessful in a given increment, the generator will temporarily halt generation. You can modify the default value of 10 cycles prior to halting particle generation.

Input File Usage

PARTICLE GENERATOR, SOLID FRACTION=threshold solid fraction, MAX ATTEMPTS PER INCREMENT=number of insertion attempts cycles

![]()

Initial conditions

Initial conditions should not be applied to nodes of particle species.

![]()

Boundary conditions

Boundary conditions can be applied to the nodes of the inlet facet to expand, shrink, or move the inlet facets of a generator.

![]()

Loads

The element set name for a species can be used to apply loads such as gravity or body loads.

![]()

Elements

The particle generator generates PD3D elements only.

![]()

Constraints

Constraints such as multi-point constraint type BEAM can be applied to the nodes of inlet facets to facilitate the application of rigid body motion to the inlet facet of a generator.

![]()

Interactions

Contact interactions between particle species are specified similar to user-defined PD3D elements. You must not include the inlet facets in the contact domain.

![]()

Output

Output is available for the element sets and node sets generated by the particle generator.

![]()

Limitations

The following limitations apply to analyses involving the particle generator:

-

Only PD3D elements can be generated.

-

It is not possible to generate clusters of PD3D elements.

-

Although supported in Abaqus/Viewer, the functionality is not supported in Abaqus/CAE.

![]()

Input file template

The following example illustrates a particle generator with two particle species:

HEADING … PARTICLE GENERATOR, NAME=generator_name, TYPE=PD3D, MAXIMUM NUMBER OF PARTICLES=number, SOLID FRACTION=number, MAX INSERTION ATTEMPTS=number, MAX ATTEMPTS PER INCREMENT=number ** PARTICLE GENERATOR INLET, SURFACE=inlet_surf ** PARTICLE GENERATOR MIXTURE gen_SET1, gen_SET2 ** PROBABILITY DENSITY FUNCTION, NAME=PDF_gen_SET1, TYPE=NORMAL Data line to define PDF PROBABILITY DENSITY FUNCTION, NAME=PDF_gen_SET2, TYPE=LOGNORMAL Data line to define PDF ** DISCRETE SECTION, ELSET=gen_SET1 PDF_gen_SET1 DISCRETE SECTION, ELSET=gen_SET2 PDF_gen_SET2 … SURFACE, TYPE=ELEMENT, NAME=inlet_surf element set name SURFACE, TYPE=ELEMENT, NAME=PG_SURF1 gen_SET1 SURFACE, TYPE=ELEMENT, NAME=PG_SURF2 gen_SET2 ** SURFACE INTERACTION,NAME=prop_gen_SET1 SURFACE INTERACTION,NAME=prop_gen_SET2 SURFACE INTERACTION,NAME=prop_gen_SET1_and_gen_SET2 ** AMPLITUDE, name=flow_speed AMPLITUDE, name=mass_flow_rate_gen_SET1 AMPLITUDE, name=mass_flow_rate_gen_SET2 ** STEP DYNAMIC, EXPLICIT ** PARTICLE GENERATOR FLOW, GENERATOR=generator_name flow_speed, mass_flow_rate_gen_SET1, mass_flow_rate_gen_SET2 ** DLOAD Data lines to define gravity load for gen_SET1 Data lines to define gravity load for gen_SET2 ** CONTACT CONTACT INCLUSIONS PG_SURF1, PG_SURF1 PG_SURF2, PG_SURF2 PG_SURF1, PG_SURF2 CONTACT PROPERTY ASSIGNMENT PG_SURF1, PG_SURF1, prop_gen_SET1 PG_SURF2, PG_SURF2, prop_gen_SET2 PG_SURF1, PG_SURF2, prop_gen_SET1_and_gen_SET2 ** END STEP