Contour integral evaluation: three-dimensional case | ||

| ||

ProductsAbaqus/Standard

Abaqus provides values of the J-integral; stress intensity factor, ; and T-stress as a function of position along a crack front in three-dimensional geometries. Several contours can be used; and, since the integral should be path independent, the scatter in the values obtained with different contours can be used as an indicator of the quality of the results. The domain integral method used to calculate the contour integral in Abaqus generally gives accurate results even with rather coarse models, as is shown in this case. Abaqus offers the evaluation of these parameters for fracture mechanics studies based on either the conventional finite element method or the extended finite element method (XFEM).

Problem description

Two geometries are analyzed in this example. In addition, both the conventional finite element method and the extended finite element method are used.

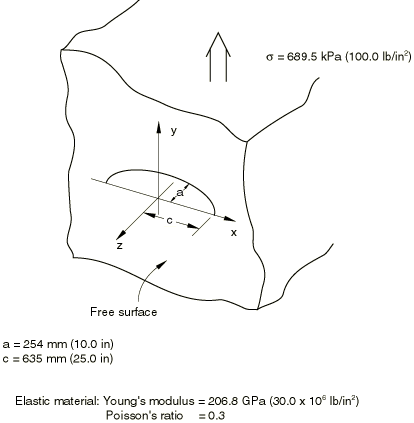

Semi-elliptic crack in a half-space

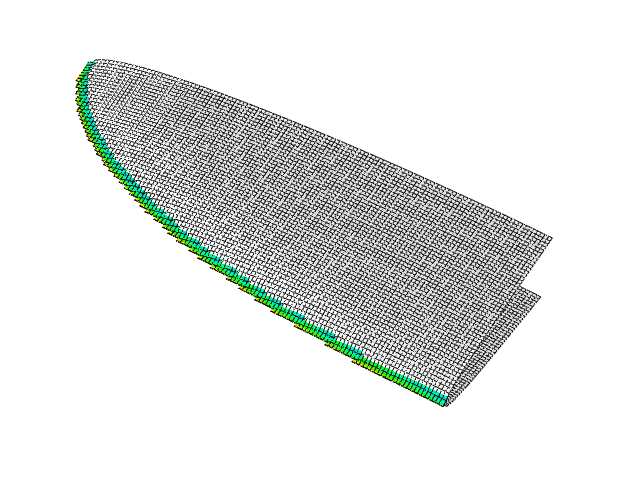

The first geometry analyzed is a semi-elliptic crack in a half-space and is shown in Figure 1. The crack is loaded in Mode I by far-field tension. When used with the conventional finite element method, due to symmetry, only one-quarter of the body needs to be analyzed. The mesh is shown in Figure 2. Reduced-integration elements (C3D20R) are used, with the midside nodes moved to the quarter-point position on those element edges that focus onto the crack tip nodes. This quarter-point method provides a strain singularity and, thus, improves the modeling of the strain field adjacent to the crack tip (see Contour integral evaluation: two-dimensional case for a discussion of this technique). The normal to the crack front is used to specify the crack extension direction, as shown in Figure 3. The mesh extends out far enough to cause the boundary conditions on the far faces of the model to have negligible effect on the solution. Three rings of elements surrounding the crack tip are used to evaluate the contour integrals.

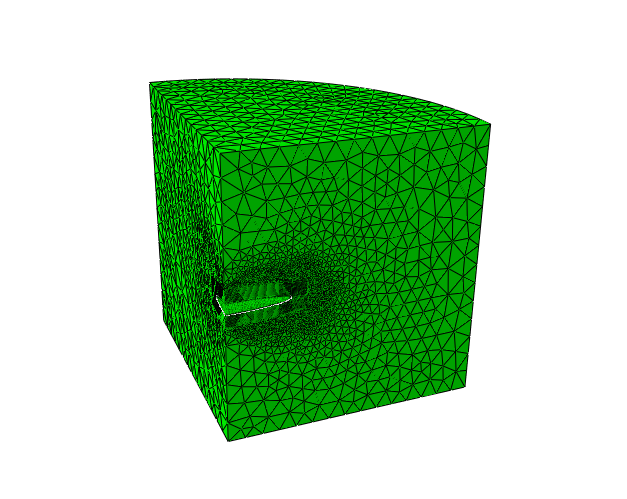

When used with the extended finite element method, the mesh is not required to match the cracked geometry. The presence of a crack is ensured by the special enriched functions in conjunction with additional degrees of freedom. This approach also removes the requirement to define the crack front explicitly or to specify the virtual crack extension direction when evaluating the contour integral. The data required for the contour integral are determined automatically based on the level set signed distance functions at the nodes in an element. The mesh with first-order brick elements (C3D8) for the first geometry is shown in Figure 4; and the crack front, which is represented by the level set contour plot of output variable PSILSM, is shown in Figure 5.

Semi-elliptic crack in a rectangular plate

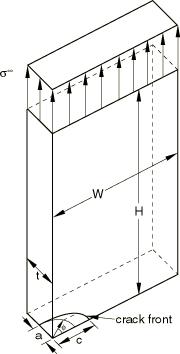

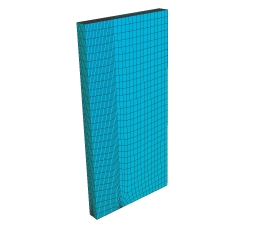

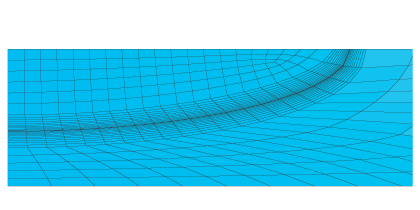

The second geometry analyzed is a semi-elliptic crack in a rectangular plate, as shown in Figure 6. The plate is subjected to uniform tension. Due to symmetry only one-quarter of the body needs to be analyzed when used with the conventional finite element method. The dimensions of the plate relative to the plate thickness, t, are as follows: the half-height 16; the half-width 8; the mid-plane crack depth 0.6; and the surface crack half-length 2.5, which results in a surface crack aspect ratio of 0.24. The mesh for the plate using the conventional finite element method is shown in Figure 7, with its profile on the crack plane shown in Figure 8. The model uses C3D8 elements for the conventional finite element method and both C3D8 and C3D4 elements for the extended finite element method.

![]()

Results and discussion

The results are presented for each of the geometries.

Semi-elliptic crack in a half-space

The J-integral values computed by Abaqus using the conventional finite element method for the first geometry are given in Table 1 as functions of angular position along the crack front, where is defined by , The values show a rather smooth variation along the crack front and are reasonably path independent; that is, the values provided by the three contours are almost the same. There is some loss of path independence and, hence, presumably, of accuracy as the crack approaches the free surface (at 0). This accuracy loss is assumed to be attributable to the coarse and rather distorted mesh in that region.

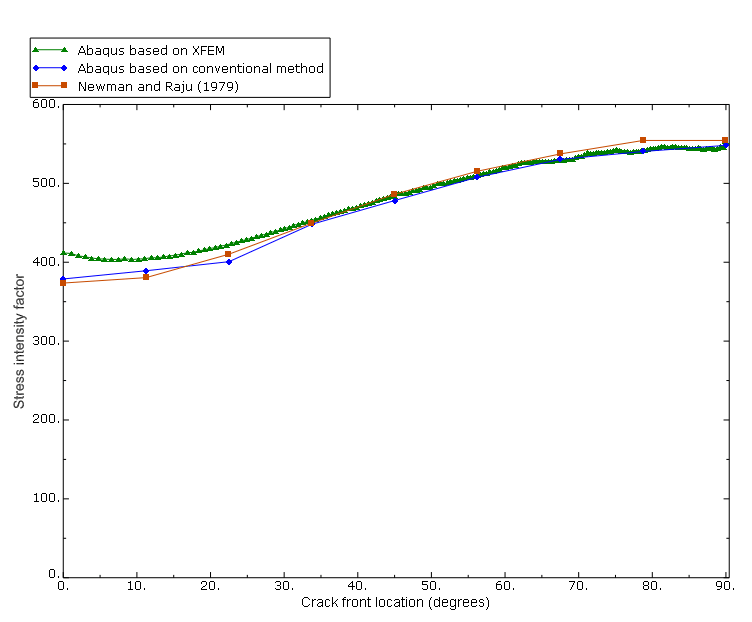

The stress intensity factors obtained using the conventional finite element method along the crack line are compared in Table 2 and in Figure 9 with those obtained by Newman and Raju (1979), who used a nodal force method to compute from a finite element model that had 3078 degrees of freedom. The J-integral values calculated by Abaqus are converted to using

where is the Poisson's ratio and E is the Young's modulus. The fourth column of Table 2 presents the stress intensity factors, , that are calculated directly by Abaqus using the conventional finite element method. For comparison, the stress intensity factors obtained using the extended finite element method are also included in Figure 9. The comparisons show good agreement with the results published by Newman and Raju (1979).

Semi-elliptic crack in a rectangular plate

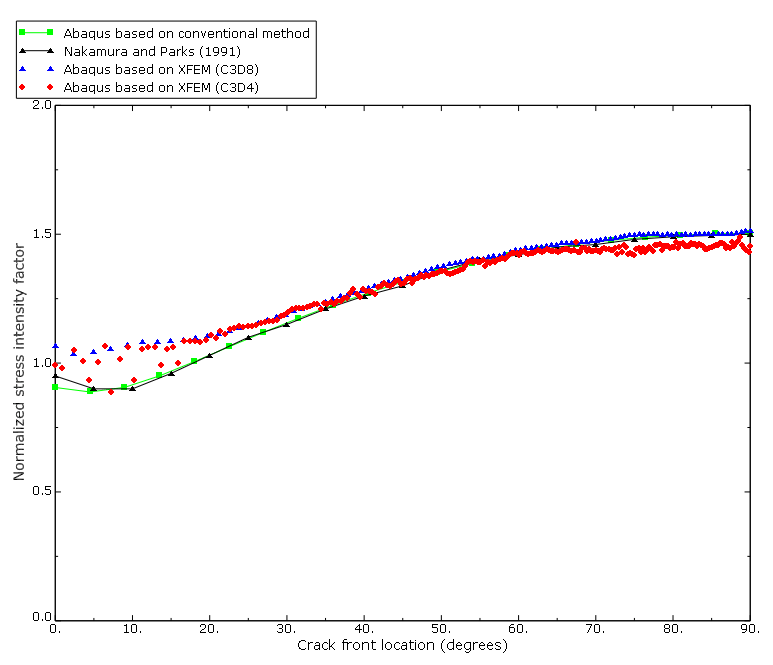

The stress intensity factor values, , computed by Abaqus based on the conventional finite element method for the second geometry are compared with the results calculated by Nakamura and Parks (1991) in Figure 10, and the agreement between them is excellent. The results obtained using the extended finite element method with linear brick or linear tetrahedron elements are also included in Figure 10 for comparison.

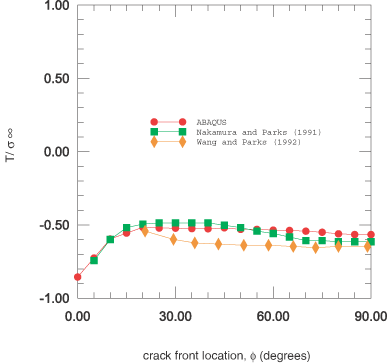

Figure 11 presents the T-stresses calculated by Abaqus and those obtained by Nakamura and Parks (1991) and Wang and Parks (1992). Comparison shows good agreement between them, especially near the middle of the crack line.

![]()

Python scripts

- Semi-elliptic crack in a half-space

Run the 3DEllipticCrackC3D20R_model.py script to create the model. Then run the 3DEllipticCrackC3D20R_job.py script to analyze the model.

- Semi-elliptic crack in a rectangular plate

Run the RectBlEllipticCrC3D8_model.py script to create the model. Then run the RectBlEllipticCrC3D8_job.py script to analyze the model.

![]()

Input files

The input files below create models with different meshes than the Abaqus/CAE models created by the Python scripts above. The results are identical in both cases.

- jintegral3d.inp

First model with conventional finite element method.

- jintegral3d_node.inp

Nodal coordinates for the first model. These have been generated by a special-purpose program.

- contourintegral_ellip_xfem_c3d8.inp

First model with extended finite element method.

- jktintegral3d.inp

Second model with conventional finite element method.

- jktintegral3d_node.inp

Node definitions for jktintegral3d.inp.

- jktintegral3d_element.inp

Element definitions for jktintegral3d.inp.

- contourintegral_ellip_plate_xfem_c3d8.inp

Second model with linear brick elements with extended finite element method.

- contourintegral_ellip_plate_xfem_c3d4.inp

Second model with linear tetrahedron elements with extended finite element method.

![]()

References

- “Determination of Elastic T-Stress along Three-Dimensional Crack Fronts Using an Interaction Integral,” International Journal of Solids and Structures, vol. 28, pp. 1597–1611, 1991.

- “Stress-Intensity Factors for a Wide Range of Semi-Elliptical Surface Cracks in Finite Thickness Plates,” Engineering Fracture Mechanics, vol. 11, pp. 817–829, 1979.

- “Evaluation of the Elastic T-Stress in Surface-Cracked Plate Using the Line-Spring Method,” International Journal of Fracture, vol. 56, pp. 25–40, 1992.

![]()

Tables

| Crack Front Location, (deg) | Contour | Average Value | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| 0.00 | 0.8081 | 0.8232 | 0.8222 | 0.8178 |

| 4.6099 | 4.6964 | 4.6907 | 4.6656 | |

| 11.25 | 0.7817 | 0.7818 | 0.7840 | 0.7825 |

| 4.4597 | 4.4599 | 4.4727 | 4.4641 | |

| 22.50 | 0.8703 | 0.8814 | 0.8834 | 0.8783 |

| 4.9647 | 5.028 | 5.0397 | 5.0108 | |

| 33.75 | 1.0300 | 1.0458 | 1.0485 | 1.0415 |

| 5.8761 | 5.9662 | 5.9817 | 5.9413 | |

| 45.00 | 1.2236 | 1.2229 | 1.2261 | 1.2242 |

| 6.9801 | 6.9762 | 6.9947 | 6.9836 | |

| 56.25 | 1.3808 | 1.3800 | 1.3836 | 1.3815 |

| 7.8771 | 7.8725 | 7.8933 | 7.8809 | |

| 67.50 | 1.4488 | 1.4723 | 1.4762 | 1.4658 |

| 8.2649 | 8.3991 | 8.4213 | 8.3617 | |

| 78.75 | 1.5746 | 1.5745 | 1.5786 | 1.5759 |

| 8.9827 | 8.9818 | 9.0053 | 8.8989 | |

| 90.00 | 1.5572 | 1.5783 | 1.5825 | 1.5727 |

| 8.8832 | 9. | 9.0275 | 8.9715 | |

| Crack Front Location, (deg) | Newman and Raju | Average Value with Conventional Method (calculated from J-integral) | Average Value with Conventional Method (calculated directly by Abaqus) |

|---|---|---|---|

| 0.00 | 12.99 | 13.64 | 13.23 |

| 373.60 | 392.19 | 380.47 | |

| 11.25 | 13.23 | 13.34 | 13.48 |

| 380.50 | 383.62 | 387.66 | |

| 22.50 | 14.26 | 14.13 | 14.06 |

| 410.20 | 406.43 | 404.52 | |

| 33.75 | 15.63 | 15.39 | 15.31 |

| 449.60 | 442.56 | 440.37 | |

| 45.00 | 16.90 | 16.68 | 16.91 |

| 486.20 | 479.82 | 486.35 | |

| 56.25 | 17.92 | 17.72 | 17.96 |

| 515.40 | 509.71 | 516.65 | |

| 67.50 | 18.68 | 18.26 | 18.16 |

| 537.30 | 525.03 | 522.23 | |

| 78.75 | 19.12 | 18.93 | 18.79 |

| 554.40 | 544.40 | 540.48 | |

| 90.00 | 19.27 | 18.93 | 18.79 |

| 554.40 | 543.84 | 546.17 |

![]()

Figures