Superelasticity | |||||||||

|

| ||||||||

ProductsAbaqus/StandardAbaqus/ExplicitAbaqus/CAE

Material behavior

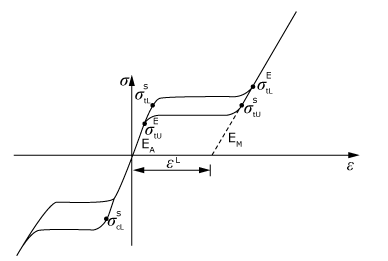

The superelastic model is based on the uniaxial stress-strain response of phase transforming materials (Figure 1). Such materials (e.g., Nitinol) are in the austenite phase under no loading conditions. Austenite is assumed to follow isotropic linear elasticity. On loading the material, the austenite phase starts transforming into martensite beyond a certain stress. Martensite is also assumed to follow isotropic linear elasticity. During the phase transformation, elastic properties are calculated from the elastic constants of austenite and martensite, following the rule of mixtures:

where is the fraction of martensite, is the Young's modulus of austenite, is the Young's modulus of martensite, is the Poisson's ratio of austenite, and is the Poisson's ratio of martensite. After a certain stress, austenite is completely transformed into martensite, which deforms elastically thereafter. Therefore, the deformation follows the elastic constants of austenite when the fraction of martensite is zero and follows the elastic constants of martensite if the fraction of martensite is one (full transformation). On unloading, martensite transforms back into austenite and the transformation strain is fully recovered. However, the stress at which the reverse transformation occurs is different from the stress at which the austenite to martensite transformation occurred.

In this model the total strain increment, , is assumed to be the sum of the elastic strain increment, , and the increment in transformation strain, :

The increment in transformation strain is calculated using the following flow rule:

where is the transformation flow potential. The transformation potential is assumed to follow the Drucker-Prager form:

where is the equivalent pressure stress, and is the Mises equivalent stress.

The transformation surface, , is also assumed to follow the Drucker-Prager form, and it varies linearly with temperature, :

In the case of tensile loading, should lie between and ; during unloading, should be between and . A difference in the response of the specimen during loading in tension and compression can be obtained by specifying a value of , which is different from . The angles and are calculated from the tensile and compressive transformation stress levels, the uniaxial transformation strain, and the volumetric transformation strain provided by the user.

You can specify the stress levels at which the transformation takes place at the reference temperature, . These stress levels are assumed to vary linearly with temperature, as shown in Figure 2.

The material data cannot be specified as a function of temperature or field variables.

![]()

Defining the elastic constants of austenite

You can define the Young's modulus and Poisson's ratio of austenite.

Abaqus/CAE Usage

Use the following option to define the elastic constants of austenite:

Property module: material editor: : Elastic

![]()

Defining the properties of martensite and the transformation plateau

You can define the elastic properties of martensite, the critical stress levels for forward and reverse transformation, and the variation of transformation plateau with temperature.

Input File Usage

Use the following option to define the elastic properties of martensite and the transformation plateau:

SUPERELASTIC

Abaqus/CAE Usage

Use the following option to define the elastic properties of martensite and the transformation plateau:

Property module: material editor:

Nonassociated transformation flow

If the value of the volumetric transformation strain is not equal to the uniaxial transformation strain, Abaqus uses a nonassociated flow rule. This results in an unsymmetric material stiffness matrix. In such cases the unsymmetric matrix storage and solution scheme should be used in Abaqus/Standard (see Defining an analysis).

Input File Usage

Use the following option to use the nonassociated transformation flow rule:

SUPERELASTIC, NONASSOCIATED=

Abaqus/CAE Usage

Use the following option to use the nonassociated transformation flow rule:

Property module: material editor: : toggle on Nonassociated, and enter the volumetric transformation strain,

![]()

Shape setting

Shape setting is done by setting all the state variables to zero. The procedure varies between Abaqus/Standard and Abaqus/Explicit. In Abaqus/Standard you must remove and reactivate elements. In Abaqus/Explicit you only need to specify the annealing process.

Input File Usage

Use the following options to define shape setting in Abaqus/Standard:

SUPERELASTIC MODEL CHANGE, REMOVE MODEL CHANGE, ADD=STRAIN FREE

Use the following options to define shape setting in Abaqus/Explicit:

SUPERELASTIC ANNEAL

Abaqus/CAE Usage

Use the following options to define shape setting in Abaqus/Standard:

Property module: material editor: Interaction module: Create Interaction: Model Change: Definition: Region, Activation state of region elements: Deactivated in this step Interaction module: Create Interaction: Model Change: Definition: Region, Activation state of region elements: Reactivated in this step

Use the following options to define shape setting in Abaqus/Explicit:

Property module: material editor: Step module: Create Step: General: Anneal

![]()

Elements

Superelasticity can be used with any stress/displacement element in Abaqus.

![]()

Output

In addition to the standard output identifiers available in Abaqus (Abaqus/Standard output variable identifiers and Abaqus/Explicit output variable identifiers), the following variables are available for the superelasticity model:

- TE

-

Transformation strain tensor.

- TEEQ

-

Equivalent transformation strain.

- TEVOL

-

Volumetric transformation strain.

- MVF

-

Fraction of martensite.

- SEQUT

-

Equivalent uniaxial tensile stress.

- EEQUT

-

Equivalent uniaxial tensile total strain.

![]()

References

- “Shape-Memory Alloys: Modeling and Numerical Simulations of the Finite-Strain Superelastic Behavior,” Computer Methods in Applied Mechanics and Engineering, vol. 143, pp. 175–194, 1996.

- “Shape-Memory Alloys: Macromodelling and Numerical Simulations of the Superelastic Behavior,” Computer Methods in Applied Mechanics and Engineering, vol. 146, pp. 281–312, 1997.