Springback analysis in Abaqus/Standard | ||

| ||

Context:

You will create a new model that imports the results from the analysis with a speedup of (mass scaling of 5) and perform a springback analysis. Thus, copy the Explicit model to a model named Import. Make all subsequent model changes to the Import model.

Since only the blank needs to be imported, begin by deleting the following features from the Import model:

Part instances Punch-1, Holder-1, and Die-1.

Sets RefDie, RefHolder, and RefPunch.

All surfaces.

All contact interactions and properties.

Both analysis steps.

Next, create a general static step named springback. Set the initial time increment to 0.1, and include the effects of geometric nonlinearity (note that the Abaqus/Explicit analysis considered them; this is the default setting in Abaqus/Explicit). Springback analyses can suffer from instabilities that adversely affect convergence. Thus, include automatic stabilization to prevent this problem. Use the default value for the dissipated energy fraction. Toggle off adaptive stabilization.

Next, define the initial state for the springback model based on the final state of the forming model.

You must redefine the boundary conditions, which are not imported. Impose the same XSYMM-type displacement boundary conditions that were imposed in the Abaqus/Explicit model on the set Center.

To remove rigid body motion, it is necessary to fix a single point in the blank, such as the node at the center of the left edge, in the 2-direction (in this way you impose no unnecessary constraints). Rather than apply a displacement boundary condition to this point, apply a zero-velocity boundary condition to fix this node at its position at the end of the forming stage (click the  tool to display the mesh in the Load module; create a node-based set at this node and then apply the appropriate boundary condition). This will allow the model to retain continuity in the blank location through any additional forming stages that may follow.

tool to display the mesh in the Load module; create a node-based set at this node and then apply the appropriate boundary condition). This will allow the model to retain continuity in the blank location through any additional forming stages that may follow.

Create a new job named springback, and submit it for analysis.

- Results of the springback analysis

Figure 1 overlays () the deformed shape of the blank after the forming and springback stages (the forming stage corresponds to the last frame of the Abaqus/Explicit output database file, while the springback stage corresponds to the final frame of the Abaqus/Standard output database file). The springback result is necessarily dependent on the accuracy of the forming stage preceding it. In fact, springback results are highly sensitive to errors in the forming stage, more sensitive than the results of the forming stage itself.

Figure 1. Deformed model shapes following forming and springback.

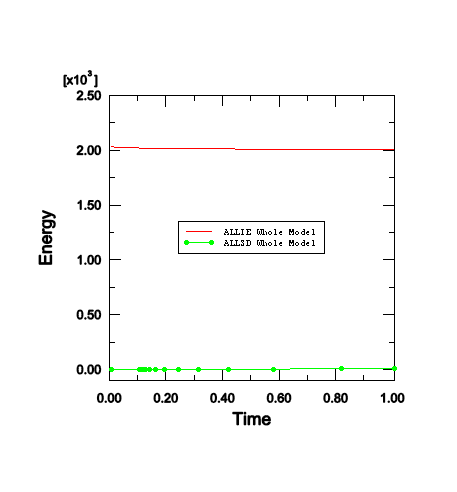

You should also plot the blank's internal energy ALLIE and compare it with the static stabilization energy ALLSD that is dissipated. The stabilization energy should be a small fraction of the internal energy to have confidence in the results. Figure 2 shows a plot of these two energies; the static stabilization energy is indeed small and, thus, has not significantly affected the results.

Figure 2. Internal and static stabilization energy histories.