Copy the existing model to a model named

Frequency. Make all of the following changes

to the Frequency model. In the frequency

extraction analysis you will replace all existing steps with a single frequency

extraction step. In addition, you will delete all of the rigid body tools and

contact interactions; they are not necessary for determining the fundamental

frequency of the blank.

Add a density of 7800 to the material

model Steel.

Delete the die, holder, and punch part instances. These rigid parts

are not necessary for the frequency analysis.

Replace the existing steps with a single frequency extraction step.

-

Delete the step Move punch.

-

In the

Model Tree,

click mouse button 3 on the step Holder force

and select Replace from the menu that appears.

-

In the Replace Step dialog box, select

Frequency from the list of available Linear

perturbation procedures. Enter the step description

Frequency modes; select the Lanczos

eigensolver option; and request five eigenvalues. Rename the step

Extract Frequencies.

-

Suppress the DOF Monitor.

Note:

Since the frequency extraction step is a linear perturbation

procedure, nonlinear material properties will be ignored. In this analysis the

left end of the blank is constrained in the

x-direction and cannot rotate about the normal;

however, it is not constrained in the y-direction.

Therefore, the first mode extracted will be a rigid body mode. The frequency of

the second mode will determine the appropriate time period for the quasi-static

analysis in

Abaqus/Explicit.

Delete all contact interactions.

Open the Boundary Condition Manager, and examine

the boundary conditions in the Extract

Frequencies step. Delete all boundary conditions except the

boundary condition named CenterBC. This leaves

the blank constrained with a symmetry boundary condition applied to the left

end.

Remesh the blank if necessary.

Create a job named Forming-Frequency

with the following job description: Channel forming --

frequency analysis. Submit the job for analysis, and monitor

the solution progress.

When the analysis is complete, enter

the Visualization module

and open the output database file created by this job. From the main menu bar,

select ; or use the

tool in the toolbox.

tool in the toolbox.

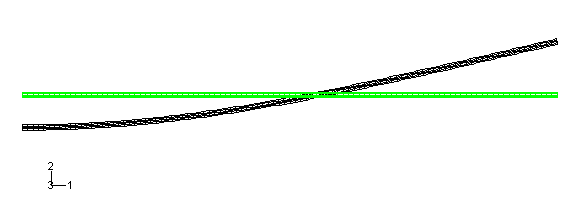

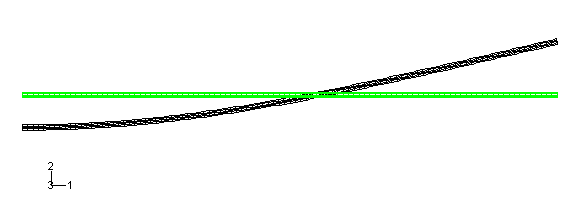

The deformed model shape for the first vibration mode is plotted (it is a

rigid body mode). Advance the plot to the second mode of the blank. Superimpose

the undeformed model shape on the deformed model shape.

The frequency analysis shows that the blank has a fundamental frequency of

140 Hz, corresponding to a period of 0.00714 s.

Figure 1

shows the displaced shape of the second mode. We now know that the shortest

step time for the forming analysis is 0.00714 s.

Figure 1. Second mode of the blank from the

Abaqus/Standard

frequency analysis.

tool in the toolbox.

tool in the toolbox.