Techniques for reducing volumetric locking | ||

| ||

Compressibility is introduced by setting the material constant to a nonzero value. The value is chosen so that the initial Poisson's ratio, , is close to 0.5. The equations given in Hyperelastic behavior of rubberlike materials can be used to relate and in terms of and (the initial shear and bulk moduli, respectively) for the polynomial form of the strain energy potential. For example, the hyperelastic material coefficients obtained earlier from the test data (see The hyperelastic material parameters in Preprocessing—creating the model with Abaqus/CAE) were given as 176051 and 4332.63; thus, setting 5.E−7 yields 0.46.

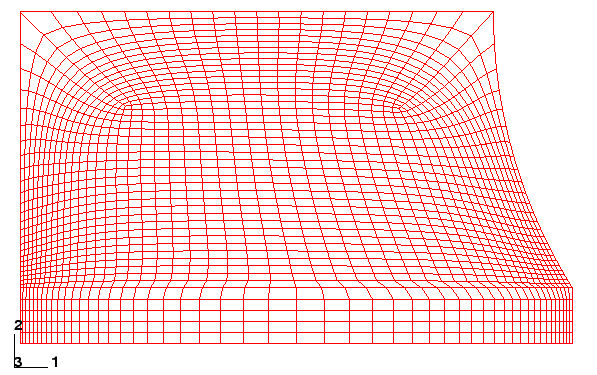

A model incorporating compressibility with additional mesh refinement (to reduce mesh distortion) is shown in Figure 1 (this mesh can be generated easily by changing the edge seeds in Abaqus/CAE or another preprocessor).

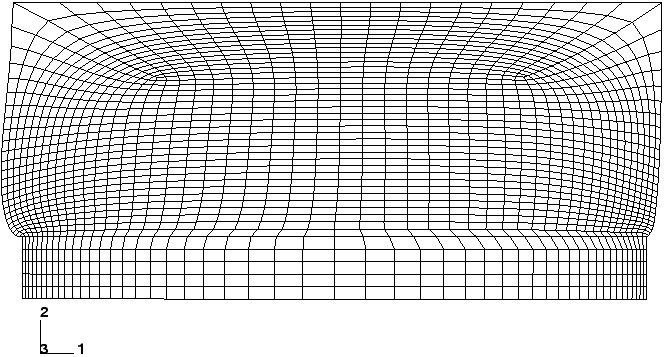

The deformed shape associated with this model is shown in Figure 2.

It is clear from this figure that the mesh distortion has been reduced significantly in the critical regions of the rubber model. Examining contour plots of the pressure (without averaging across elements) reveals a smooth variation in pressure stress between elements. Thus, volumetric locking has been eliminated.