Creating the model to analyze | ||

| ||

The problem investigates the effects on the accuracy of the bending moment computed at the center of a shell using:

-

different shell formulations and

-

at different angles.

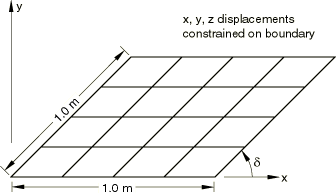

Figure 1 illustrates the basic geometry of the simply supported skew plate with a uniform distributed load.

The plate is loaded by a uniform pressure of 1.0 × 10−6 MPa applied over the entire surface. The edges of the plate are all simply supported. The analysis is performed for five different values of the skew angle, : 90°, 80°, 60°, 40°, and 30°. The analysis is performed for two different quadrilateral elements: S4 and S8R.

The example is divided into two scripts. The controlling script, skewExample.py, imports skewExampleUtils.py. Use the fetch utility to retrieve the scripts:

abaqus fetch job=skewExample abaqus fetch job=skewExampleUtils

You should use Abaqus/CAE to create your model and to save the resulting model database. You will then use scripting to parameterize your model, submit an analysis job, and operate on the results generated.

Start Abaqus/CAE, and create a model database from the Start Session dialog box. By default, you are operating on a model named Model-1. The model should include the following:

- Part

-

Create a three-dimensional planar shell part, and name it Plate. Use an approximate size of 5.0. All sides are 1.0 m long. Delete all perpendicular and vertical constraints, and apply the following constraints:

-

a fixed constraint to the lower-left vertex,

-

horizontal constraints to the top and bottom edges (if they are not already defined), and

-

parallel constraints to the left and right edges

-

- Material

-

Create a material, and name it Steel. The Young's modulus is 30 MPa, and the Poisson's ratio is 0.3.

- Section

-

Create a homogeneous shell section that refers to the material called Steel. Name the section Shell. The plate thickness is 0.01 m. The length/thickness ratio is, thus, 100/1 so that the plate is thin in the sense that transverse shear deformation should not be significant. Assign the section to the plate.

- Assembly

-

Create the assembly using a single, independent part instance of Plate. Abaqus/CAE names the part instance Plate-1. Creating an independent part instance means that the mesh is based at the assembly level.

- Step

-

Create a static step and name it Step-1. Enter Apply pressure for the step Description. Accept the default time period of 1.0 and the default initial increment of 1.0.

- Output database requests

-

Edit the default output database request for field output and select only U, Translations and rotations, and SF, Section forces and moments, for the whole model after every increment. Delete all requests for history output.

- Boundary condition

-

Create a displacement boundary condition, and name it Pinned. The boundary condition pins the exterior edges of the plate.

- Load

-

Create a pressure load, and name it Pressure. Apply the load to the face of the plate. Accept the default side of the plate and use a magnitude of 1.0. This positive pressure will result in a negative displacement in the 3-direction.

- Set

-

Partition the plate into quarters by sketching lines between the midpoints of the four edges. Create a set that contains the vertex at the center of the plate, and name the set CENTER.

- Mesh

-

Create a 4 × 4 swept mesh of quadrilateral elements on the plate.

- Keyword editor

-

You must use the Keyword Editor to request output of section forces and moments for the node at the center of the plate. When you edited the output database request to select the variable, SF, Abaqus/CAE requested output of section forces and moments at element integration points. To modify this output request, you must add position=NODES to the OUTPUT REQUESTS block as follows:

*Element Output, position=NODES SF,

- Job

-

Create a job, and name it skew. The job must refer to the model Model-1.