Understanding bolt loads | ||

| ||

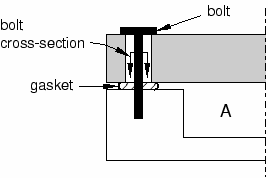

Figure 1 shows a container (A) that is sealed by tightening the bolts that hold the lid, which places the gasket under pressure.

You can model the tension in the tightened bolts by applying a bolt load to each one in the first step of the analysis. You define the load in terms of either a concentrated force or a prescribed change in length, and you apply the load across a bolt cross-section surface that you specify. In later steps you can modify the load to prevent further length changes so that the bolt acts as a standard, deformable component responding to other loadings on the assembly.

When you create a bolt load, you must specify the following:

- A surface that defines the bolt cross-section

-

Abaqus/CAE applies the bolt load across the cross-section surface that you specify. The surface that defines the bolt cross-section must cut through the bolt geometry. Abaqus/CAE creates an interior surface at that location.

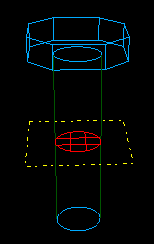

If you are working with bolt part instances made from native or imported geometry, Abaqus/CAE can create an interior surface by partitioning the bolt shank surface, or you can partition the bolt at the location where you want the cross-section to be defined. For example, a partition is selected as the bolt cross-section in Figure 2. For more information, see The Partition toolset.

Figure 2. Using a partition to specify the bolt cross-section.

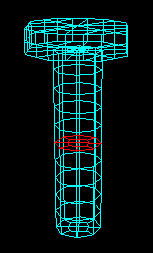

If you are working with orphan mesh elements, you must specify the cross-section surface by selecting element faces. For example, element faces define a cross-section surface for the mesh part shown in Figure 3.

Figure 3. Using element faces to specify the bolt cross-section.

The element faces need to be selected from elements on only one side of the pre-tension section. You can use display groups to remove selected elements from the viewport to reveal the element faces of the cross-section surface. For more information on selecting surfaces, see Selecting objects within the viewport. For detailed information on selecting surfaces on wire part instances, see Specifying a particular side or end of a region.

Note:

You can apply bolt loads only to three-dimensional solid, two-dimensional solid, and three-dimensional wire part instances. Bolt loads on two-dimensional and axisymmetric wire part instances are unsupported.

- A bolt axis

-

If you are defining a bolt load on a solid region, the surface normal of the surface that defines the bolt cross-section is used as the bolt axis by default. You can select a datum axis to indicate a different bolt axis direction (it need not be normal to the cross-section). If you are defining a bolt load on a wire region, the bolt axis direction is always assumed to be the direction of the tangent to the wire at the bolt cross-section.

Abaqus/CAE uses both the cross-section surface that you specify and the bolt axis to define the pre-tension section data and the pre-tension reference node used by Abaqus/Standard; see Prescribed Assembly Loads for more information. You can create the pre-tension section at the part level or the assembly level. To create the pre-tension section at the part level, the selected region must belong to a dependent part instance. If you create the pre-tension section at the part level, the bolt load is defined for all of the instances from the same part.

- A method for applying the loading

-

When you create a bolt load, you must choose one of the following loading methods:

-

Apply a force to the bolt. This method models tightening the bolt so that it carries a specified load.

-

Adjust the bolt length. This method models tightening the bolt until its free length has changed by the specified value.

-

Fix the bolt at its current length. This method is available only if you have already created the load in the first analysis step and are now editing it in a subsequent analysis step. This method allows the bolt length to remain unchanged so that the force in the bolt can change according to the response of the model.

-

- A magnitude for the chosen method

-

If you are applying a force to the bolt, you must enter the force magnitude. If you are adjusting the bolt length, you must enter the length change.

You can create a bolt load only in the first analysis step, but you can modify the loading method or the magnitude of the load in subsequent steps. For example, you can apply a specific tension in the first step and then change the method in the second step to fix the bolt length.

You can obtain data from a bolt load using the field and history output request editors in the Step module. In the Domain section of the editor, select Bolt load and choose the desired bolt load from the menu that appears. For more information, see Creating an output request.

For detailed information on creating a bolt load, see Creating and editing bolt loads.