Uniformly loaded, elastic-plastic plate | ||

| ||

ProductsAbaqus/Standard

Problem description

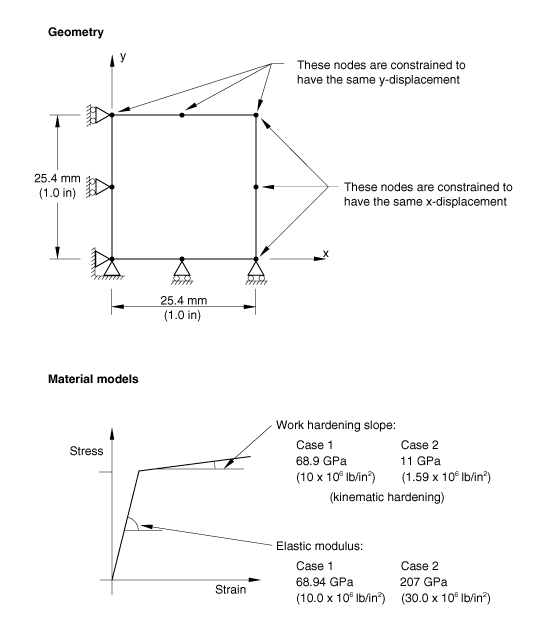

The material models for the unixially and biaxially loaded cases are described below.

Case 1—Uniaxial loading

Figure 1 shows the material model for this case. The elastic modulus is 68.94 GPa (10.0 × 106 lb/in2), the yield stress is 68.9 MPa (10.0 × 103 lb/in2), and the work hardening slope is 68.9 GPa (10.0 × 106 lb/in2). This is specified by giving a yield stress of 34.57 GPa (5.01 × 106 lb/in2) at a plastic strain of 0.5. The total force and the total moment on the loaded face of the model are output to the results file.

Case 2—Biaxial loading

Figure 1 shows the material model for this case. The elastic modulus is 207 GPa (30.0 × 106 lb/in2), the yield stress is 207 MPa (30.0 × 103 lb/in2), and the work hardening slope is 11 GPa (1.59 × 106 lb/in2). This is specified by giving a yield stress of 10.62 GPa (1.53 × 106 lb/in2) at a plastic strain of 0.95.

![]()

Model and loading

The geometries and loading distributions for the unixial and biaxial cases are described below.

Case 1—Uniaxial loading

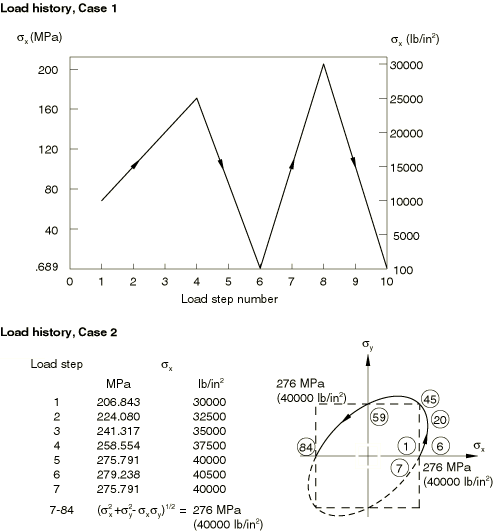

Figure 1 shows the geometry for this case. Two types of meshes are provided: a single-element mesh using higher-order plane stress and shell elements (CPS8R, S8R5, S9R5, and STRI65) and a mesh using linear shell and continuum shell elements (S4R and SC8R). Two edges have simple support. The load history is shown in Figure 2 and is prescribed with an amplitude curve (Amplitude Curves). The load distribution is a uniform, direct stress on the element edge. Since the strain should be uniform, the edge nodes are constrained using an equation constraint (Linear constraint equations) to move together in the direction normal to the edge. Then the total load on the edge is simply given on one of the edge nodes.

Case 2—Biaxial loading

The case is set up with the same geometric model (Figure 1). However, the loading is more complex (see Figure 2).

First, the plate is loaded into the plastic range in uniaxial tension in the x-direction, unloaded slightly, and reloaded. Biaxial loading then follows, with and prescribed, as shown in Figure 2, so that the quantity remains constant at 276 MPa (40000 lb/in2). This loading is defined by an amplitude curve by reading in a file of values previously calculated in the small program AMP (see elasticplasticplate_amplitude.f).

![]()

Results and discussion

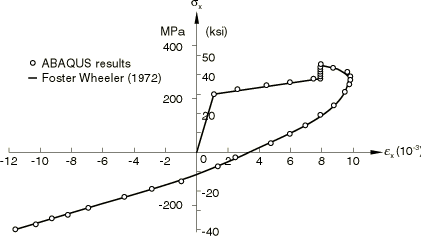

Exact solutions for these two problems have been developed by Chern in a Foster Wheeler report (1972), where they are documented as Problems 8 and 9. These solutions provide a basis for the comparison of the Abaqus results.

Case 1—Uniaxial loading

Case 2—Biaxial loading

The results in this case are best represented by the versus plot shown in Figure 3. The agreement with the exact solution is again very close.

![]()

Input files

- elasticplasticplate_cps8r_uni.inp

Uniaxial loading case using the CPS8R element.

- elasticplasticplate_cps8r_bi.inp

Biaxial loading case using the CPS8R element.

- elasticplasticplate_amplitude.f

Program used to generate the amplitude data records.

- elasticplasticplate_s8r5_uni.inp

Uniaxial loading case using the S8R5 element.

- elasticplasticplate_s8r5_bi.inp

Biaxial loading case using the S8R5 element.

- elasticplasticplate_s9r5_uni.inp

Uniaxial loading case using the S9R5 element.

- elasticplasticplate_s9r5_bi.inp

Biaxial loading case using the S9R5 element.

- elasticplasticplate_stri65_uni.inp

Uniaxial loading case using the STRI65 element.

- elasticplasticplate_stri65_bi.inp

Biaxial loading case using the STRI65 element.

- elasticplasticplate_s4r_uni.inp

Uniaxial loading case using the S4R element.

- elasticplasticplate_s4r_bi.inp

Biaxial loading case using the S4R element.

- elasticplasticplate_sc8r_uni.inp

Uniaxial loading case using the SC8R element.

- elasticplasticplate_sc8r_bi.inp

Biaxial loading case using the SC8R element.

![]()

References

- “Intermediate Heat Exchanger for Fast Flux Test Facility: Evaluation of the Inelastic Computer Programs,” report prepared for Westinghouse ARD, Foster Wheeler Corporation, Livingston, NJ, 1972.

- “Accuracies of Numerical Solution Methods for the Elastic-Perfectly Plastic Model,” ASME Journal of Pressure Vessel Technology, vol. 99, no. 4, pp. 510–515, 1977.

- “Accurate Numerical Solutions for Elastic-Plastic Models,” ASME Journal of Pressure Vessel Technology, vol. 101, no. 3, pp. 226–234, 1979.

![]()

Tables

| Load increment | Number of iterations | (10−3) | |||

|---|---|---|---|---|---|

| (MPa) | (lb/in2) | (Abaqus) | (exact) | ||

| 1 | 1 | 68.947 | 10000 | 0 | 0 |

| 2 | 1 | 103.422 | 15000 | 0.500 | 0.500 |

| 3 | 1 | 137.895 | 20000 | 1.000 | 1.000 |

| 4 | 1 | 172.369 | 25000 | 1.500 | 1.500 |

| 5 | 3 | 86.529 | 12550 | 1.500 | 1.500 |

| 6 | 2 | 0.69 | 100 | 1.010 | 1.010 |

| 7 | 3 | 103.77 | 15050 | 1.010 | 1.010 |

| 8 | 2 | 206.83 | 30000 | 2.000 | not shown |

| 9 | 3 | 103.77 | 15050 | 2.000 | not shown |

| 10 | 2 | 0.69 | 100 | 1.010 | 1.010 |

![]()

Figures