Demoldable surface (SURF_DEMOLD) | ||||||

|

| |||||

| CLIENT / Applicable for | Controller (SHAPE_CONTROLLER) | Sensitivity (SHAPE_SENSITIVITY) |

|---|---|---|

| SURF_DEMOLD | OK | OK |

Controller based optimization

Defining a demolding or forging restriction involves specifying the manufacturing direction. The area to restrict is defined using a node group of surface nodes. Demolding in the specified direction or forging against this direction is maintained during optimization and undercuts are avoided. The link condition for the demold restriction is defined as follows:

CLIENT = SURF_DEMOLD

DEMOLD_DIR = <x_1>,<x_2>,<x_3>

CS = name_of_coord_system

CHECK_GROUP = name_of_node_group

TOL = <tol_1>, <tol_2>, <tol_3>

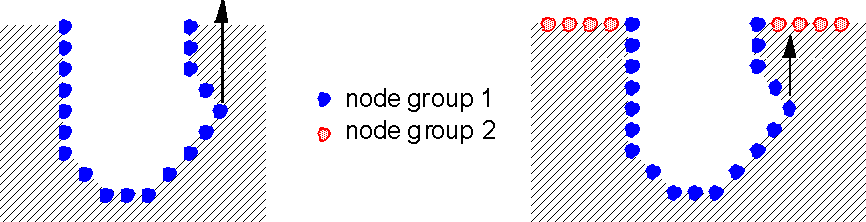

The direction defined by the DEMOLD_DIR specifies the demolding direction respectively the negative forging direction. All nodes in the node group are checked for undercuts and for demolding against the specified CHECK_GROUP. This group of surface nodes should qualify the cast sufficiently. In the simplest case the group of all surface nodes can be chosen. In the following fiugure node group 1 describes the demolding area. If the check group contains only node group 1 the undercut is not detected because the check group describes no restricting surface. Only node group 1 and 2 together qualify a surface to detect undercuts reliably.

In addition, an angle for the surface inclination may be specified using the ANGLE parameter:

ANGLE = <real>

|

The undercut tolerance specifies the maximum valid undercut (default = 0):

UNDERCUT_TOL = <real>

Important:

|

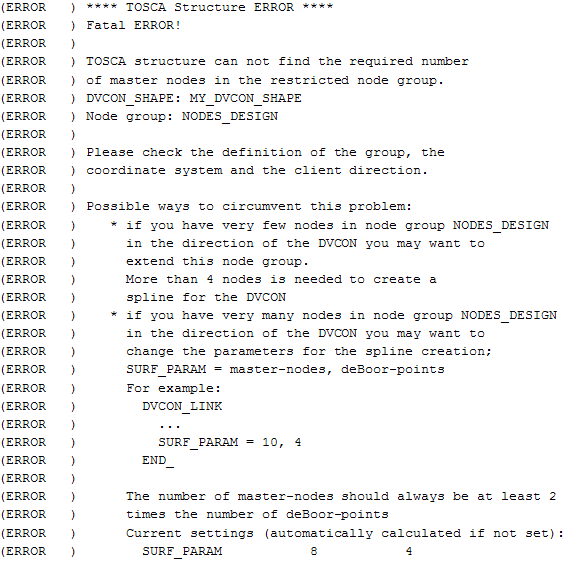

- In the event of an error like

it may help setting SURF_PARAM. Important is that <master_areas> must be larger than 4 and at least double the size of <net_points>. Good values are e.g. SURF_PARAM = 12, 4.

Important:

|

![]()

Sensitivity based optimization

The commands used to set up the demold manufacturing constraint for sensitivity based shape optimization does not differ much

from how to set it up for the controller based shape optimization, but the enforcement happens in another way.

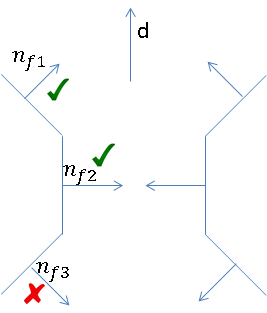

For the sensitivity approach, a face is enforced to be demoldable by adding a constraint to the optimization problem stating that

the angle between the face normal vector and the demold direction must be less (or equal) to 90°.

Since too many optimization constraints slow down the optimization process too much, the constraints for one demold command are aggregated into one single constraint by summing up the single constraints:

Two parameters that influence the behavior of the aggregation are

AGGREGATION_PARAMETER=<real>and

AGGREGATION_NUM_CONSTRAINTS=<int>.AGGREGATION_PARAMETER is used as the power in the aggregation method and AGGREGATION_NUM_CONSTRAINTS is used to switch back to the "one constraint per face" strategy. To do so, select AGGREGATION_NUM_CONSTRAINTS=-1

A command example might look like the following snipped.

LINK_SHAPE

ID_NAME = demold

CLIENT = SURF_DEMOLD

DEMOLD_DIR = 0.,0.,1.

CS = CS_0

ANGLE = 0.0

END_

DVCON_SHAPE

ID_NAME = dvcon_demold

ND_GROUP = demold_nodes

CHECK_LINK = demold

END_

The faces covered by the node group demold_nodes shall be demoldable in z-direction.

Consider, that no master criteria is used (it would be ignored anyways).s