Plane symmetry for non-symmetric meshes (SURF_PLANE_SYM) | ||||||

|

| |||||

| CLIENT / Applicable for | Controller (SHAPE_CONTROLLER) | Sensitivity (SHAPE_SENSITIVITY) |

|---|---|---|

| SURF_PLANE_SYM | OK | OK |

To be able to couple displacements symmetrically to a plane on not necessarily symmetrically meshed geometries, the position and the orientation of the plane must be specified. The following four parameters are necessary for the definition of the link condition:

CLIENT = SURF_PLANE_SYM

CLIENT_DIR = <X_1>, <X_2>, <X_3>

CS = name_of_coord_system

TOL = tolerance_value

The origin of the coordinate system referenced by CS defines a point on the symmetry plane. The direction specified by the CLIENT_DIR parameter defines the normal of the plane. The tolerance value specified by TOL is used as absolute tolerance in intersection tests and can be used to influence the behaviour on the border of the selected node group.

The symmetry of the nodes (assigned by ND_GROUP in the DVCON_SHAPE command) is checked against the symmetry plane. For each node a reference displacement is calculated for its symmetric "counterpart". This counterpart is obtained by reflecting the node at the symmetry plane, i.e. by intersecting a line through the node in plane normal direction with the surface defined by all selected nodes. The reference displacement is obtained by interpolation of the optimization displacements of the adjacent nodes. The tolerance is required to find reference displacements at the border of the selected node group, where it will happen that nodes do not have an opposite face (with respect to the plane definition) and thus no intersection points in plane normal directions can be found.

Optional, a strategy to determine node position influence on the result can be chosen:

MASTER = MAX | MIN

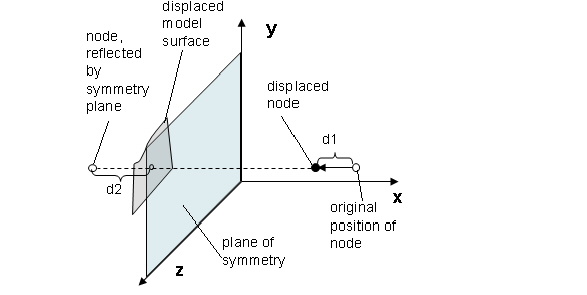

The symmetry is built up by using the maximum (default) or the minimum of the displacement of the selected node (d1 in the following figure) and the interpolated displacement of its plane symmetric counter part (reference displacement d2 in the following figure).

|

Important:

|

Special considerations when using shape sensitivity

This coupling condition is applicable for sensitivity based shape optimization. However, the two approaches work in different ways. For the sensitivity based optimization, the optimization problem is solved only on one halve of the symmetry group and the results (i.e. the design variable values) are transferred to the missing part.

- The MASTER command is not evaluated. Instead the "active" part is determined by the direction of the plane normal: The "active"/"master" lies on the side of the plane where the plane normal direction points to.

- This is especially important when combining several plane restrictions. The later restrictions have to lie in the "active" area of the previous restriction.

- If the reflection of a node near the symmetry plane lies in a face that is cut by the symmetry plane, then this node also becomes part of the "active"/"master" area. This might lead to non-symmetries near the symmetry plane. These non-symmetries can get distributed to neighboring nodes through design variable filtering (which is activated by default).