Demold Constraints with Parameterization Filter | ||

| ||

It enforces the demolding constraint by grouping the elements in the demolding direction and parameterizing the respective densities. Hence, as a mathematical approach, it will ensure a castable design, independently of the combination of objective function and constraints that the user selects.

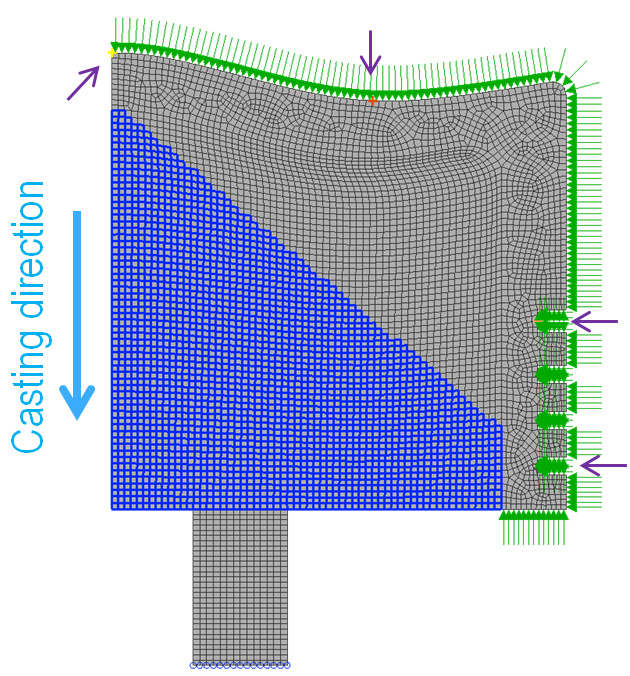

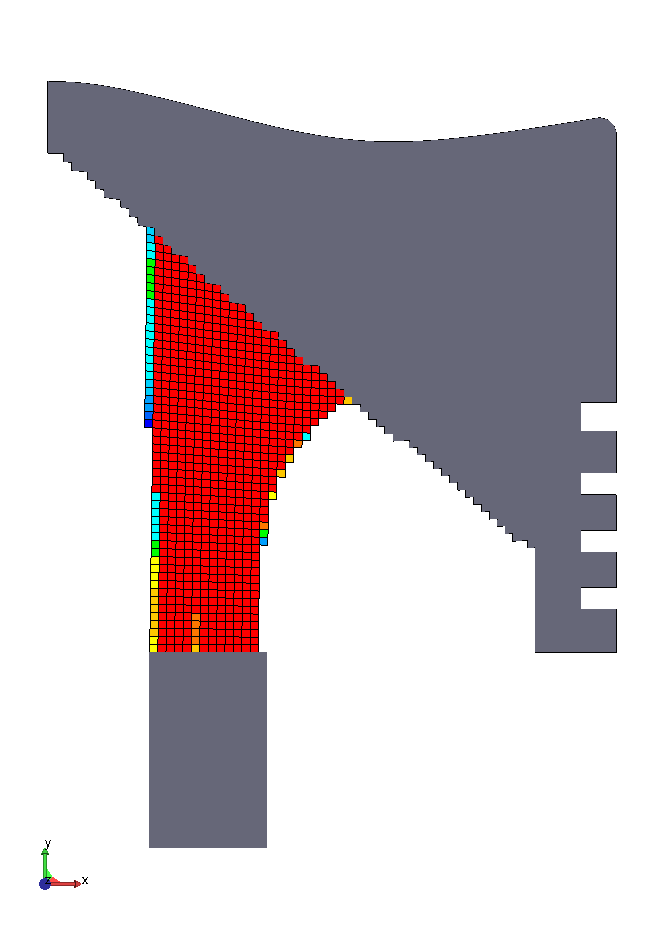

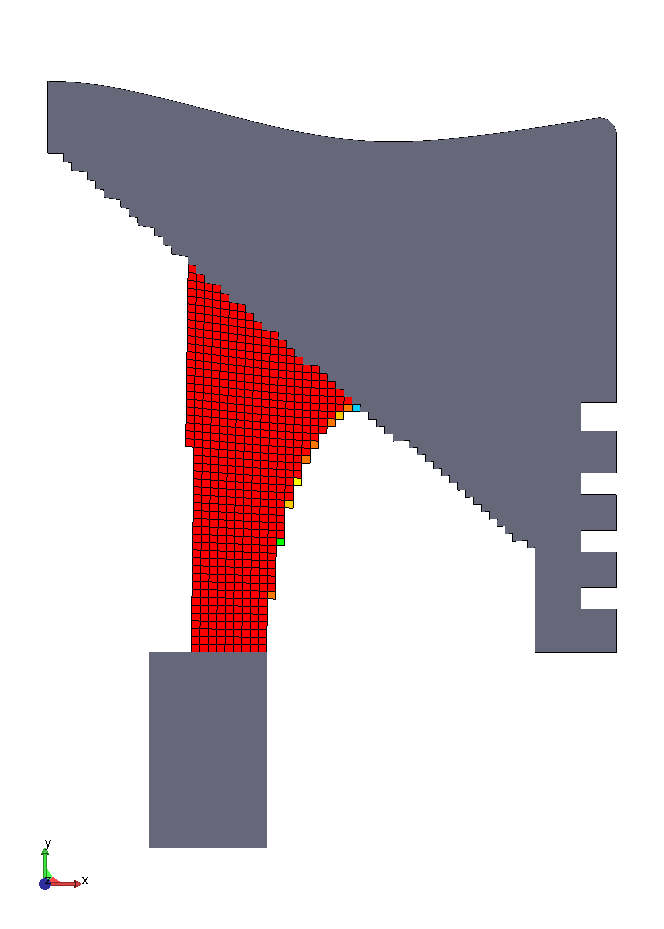

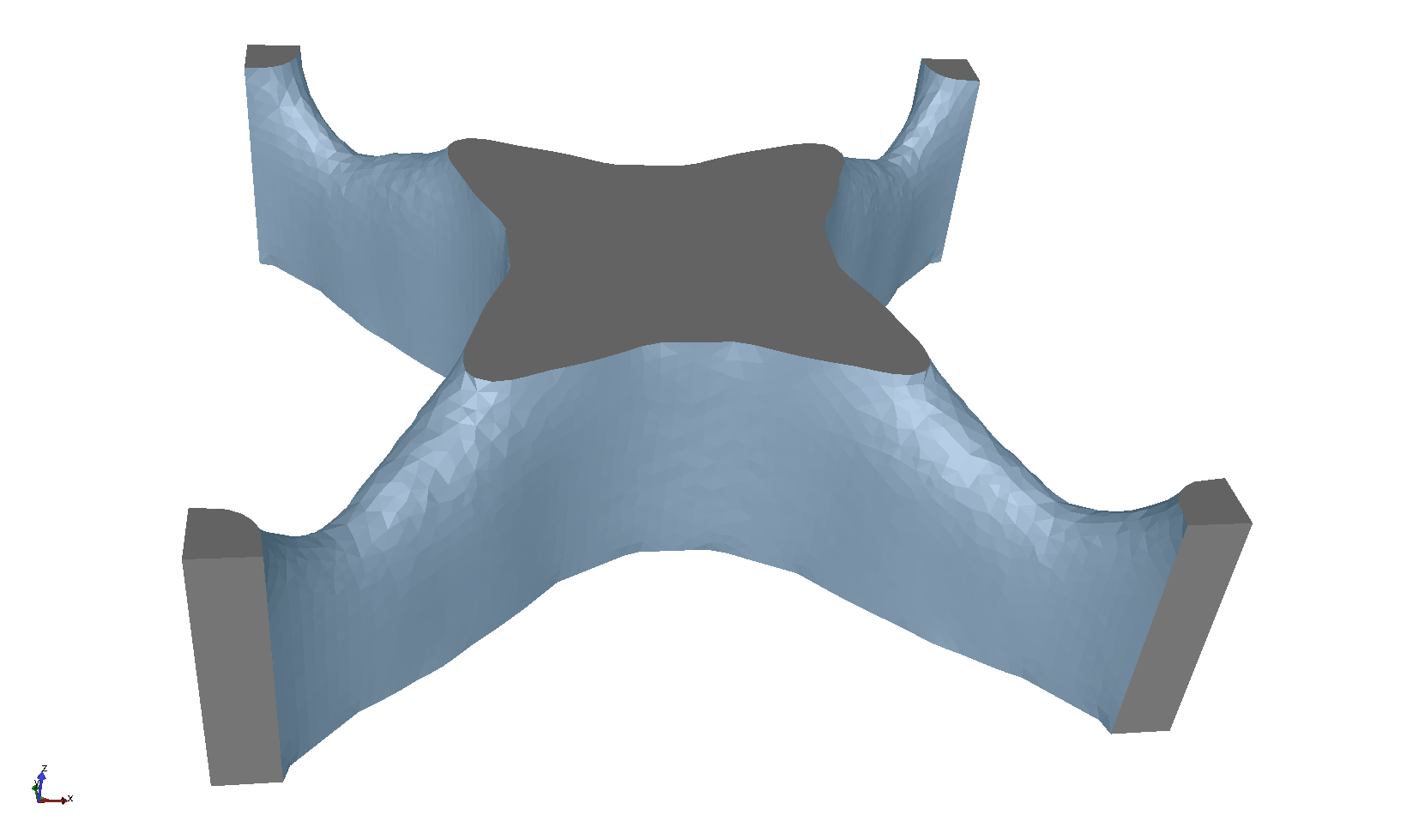

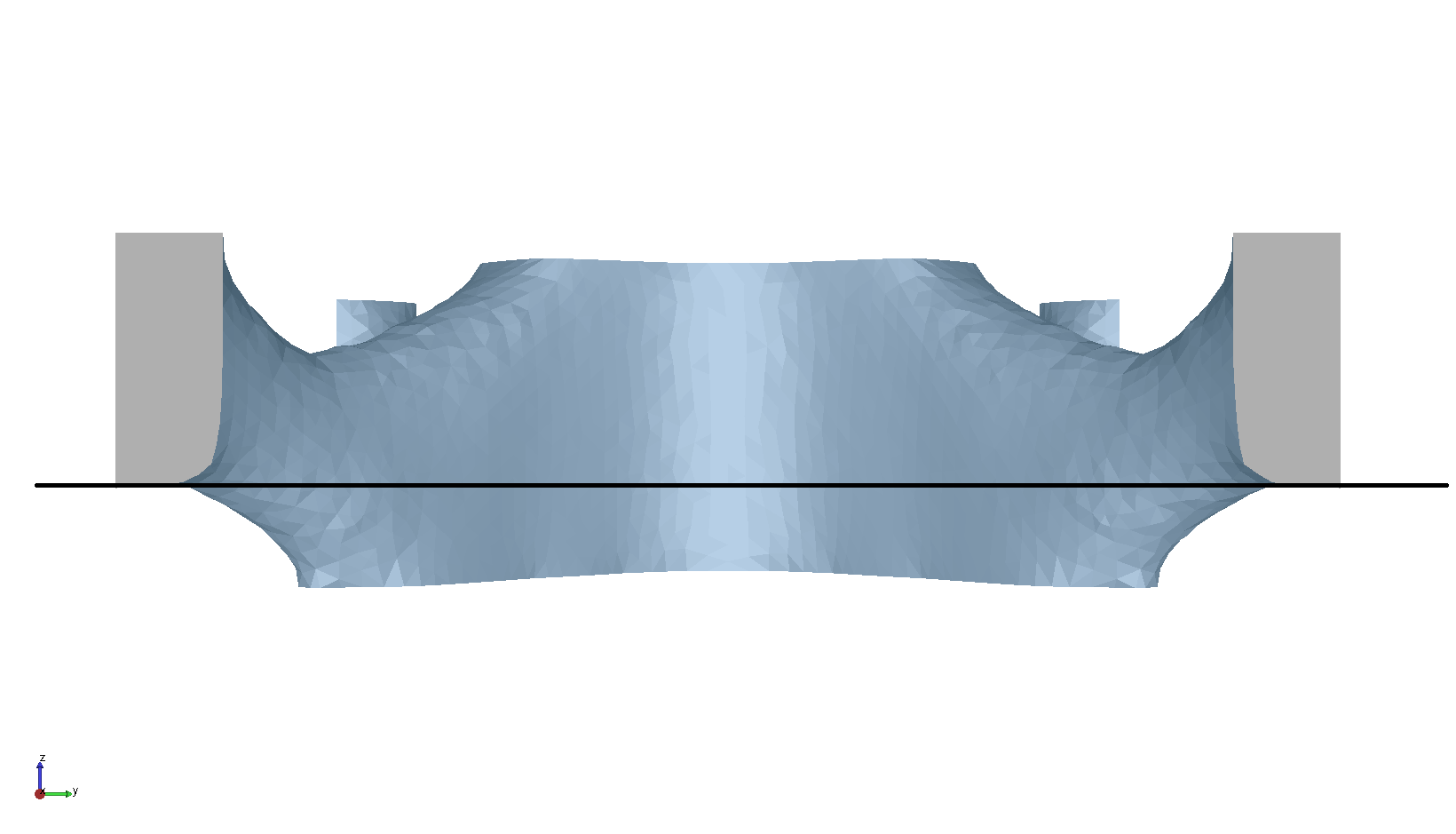

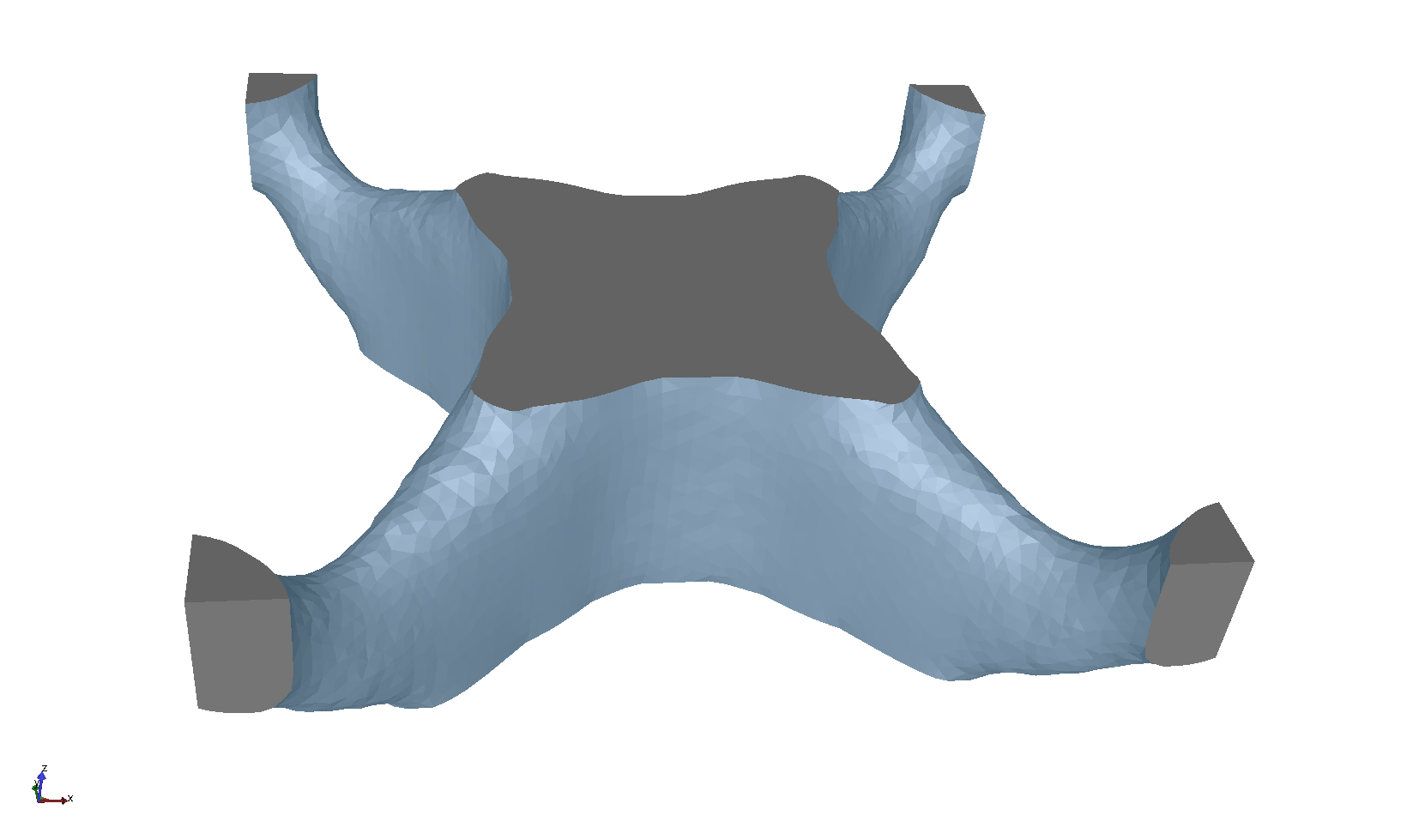

Therefore, this algorithm yields better results for applications where the previous approach failed in achieving manufacturable designs, for instance with axisymmetric models as the following example illustrates:

| Example | FILTER_PARAM = NO | FILTER_PARAM = YES |

|---|---|---|

|

Piston head - axisymmetric model:

|

|

|

|

|

|

Besides this advantage, it tends to require the same or a slightly inferior number of optimization iterations when compared with the default approach.

This option is disabled by default and can be selected by adding the command FILTER_PARAM = YES inside the DVCON_TOPO block for sensitivity based topology optimizations:

DVCON_TOPO

ID_NAME =

EL_GROUP =

CHECK_TYPE = CAST

PULL_DIR =

CHECK_GROUP =

MID_PLANE =

PULL_CS =

ANGLE = 0

FILTER_PARAM = YES

END_This option can be combined with the remaining restrictions, such as frozen area, symmetry and member size control. Regarding the parting surface definition only the following options are supported:

- MID_PLANE = STAMP

- MID_PLANE = NONE

- MID_PLANE = POINT

- MID_PLANE = AUTO

The different possible restrictions are illustrated in the following figure:

| MID_PLANE = STAMP | MID_PLANE = NONE | MID_PLANE = POINT | MID_PLANE = AUTO |

|---|---|---|---|

|

|

|

|

The specification of a deformation angle (ANGLE) different than zero or the remaining parting surface definitions (MID_PLANE = AUTO_TIGHT or MID_PLANE = SURFACE ) are not compatible with this approach and therefore should be combined with the default option: FILTER_PARAM = NO.

Notes:

- Defining a pull restriction causes many restrictions for 2D models. If the topology optimization with pull direction is to be carried out on 2D models, the settings for the DENSITY_UPDATE and the DENSITY_MOVE (for instance DENSITY_MOVE = 0.10) in the optimization parameters block (OPT_PARAM) may have to be adjusted to smaller or more conservative values to ensure convergence of the algorithm.

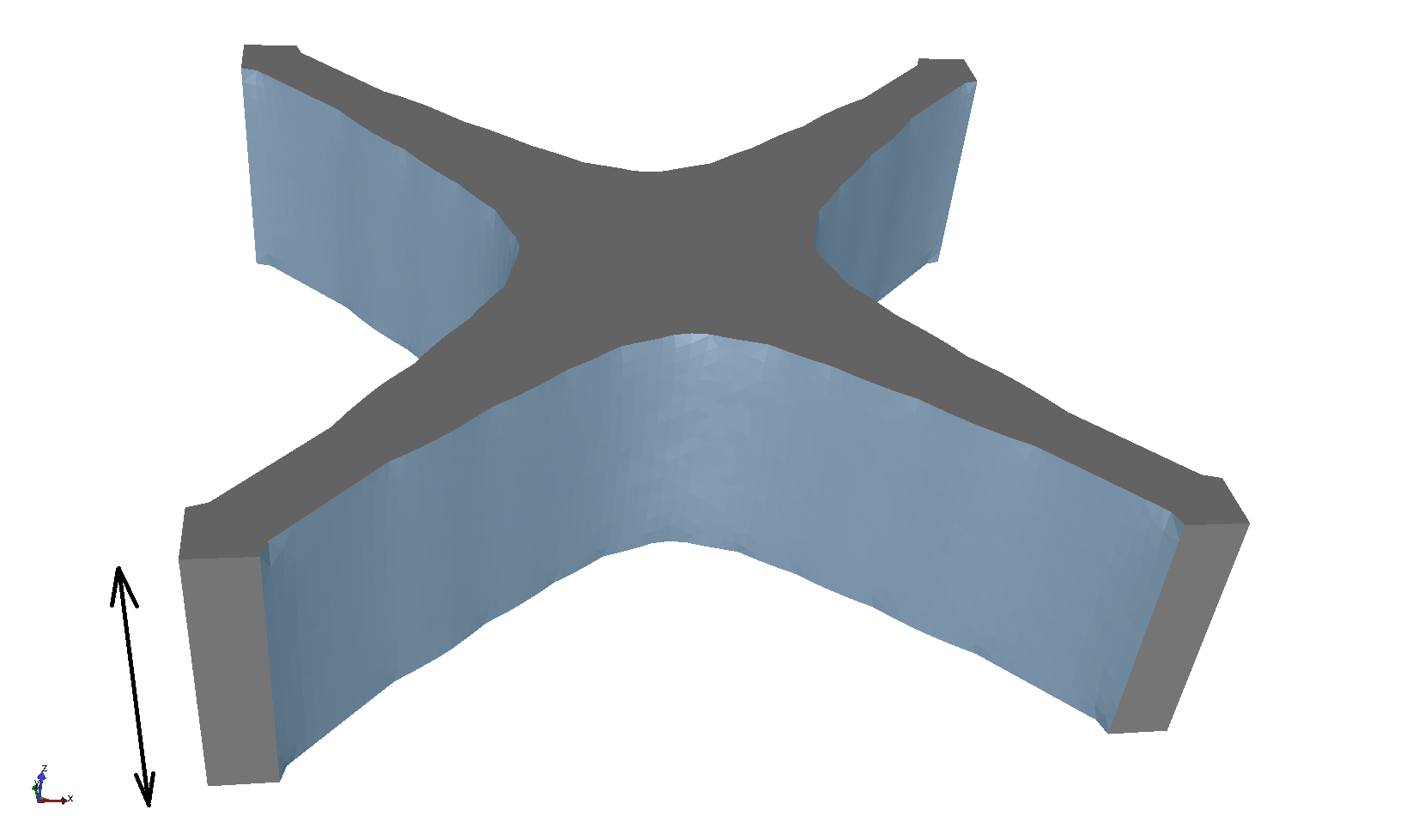

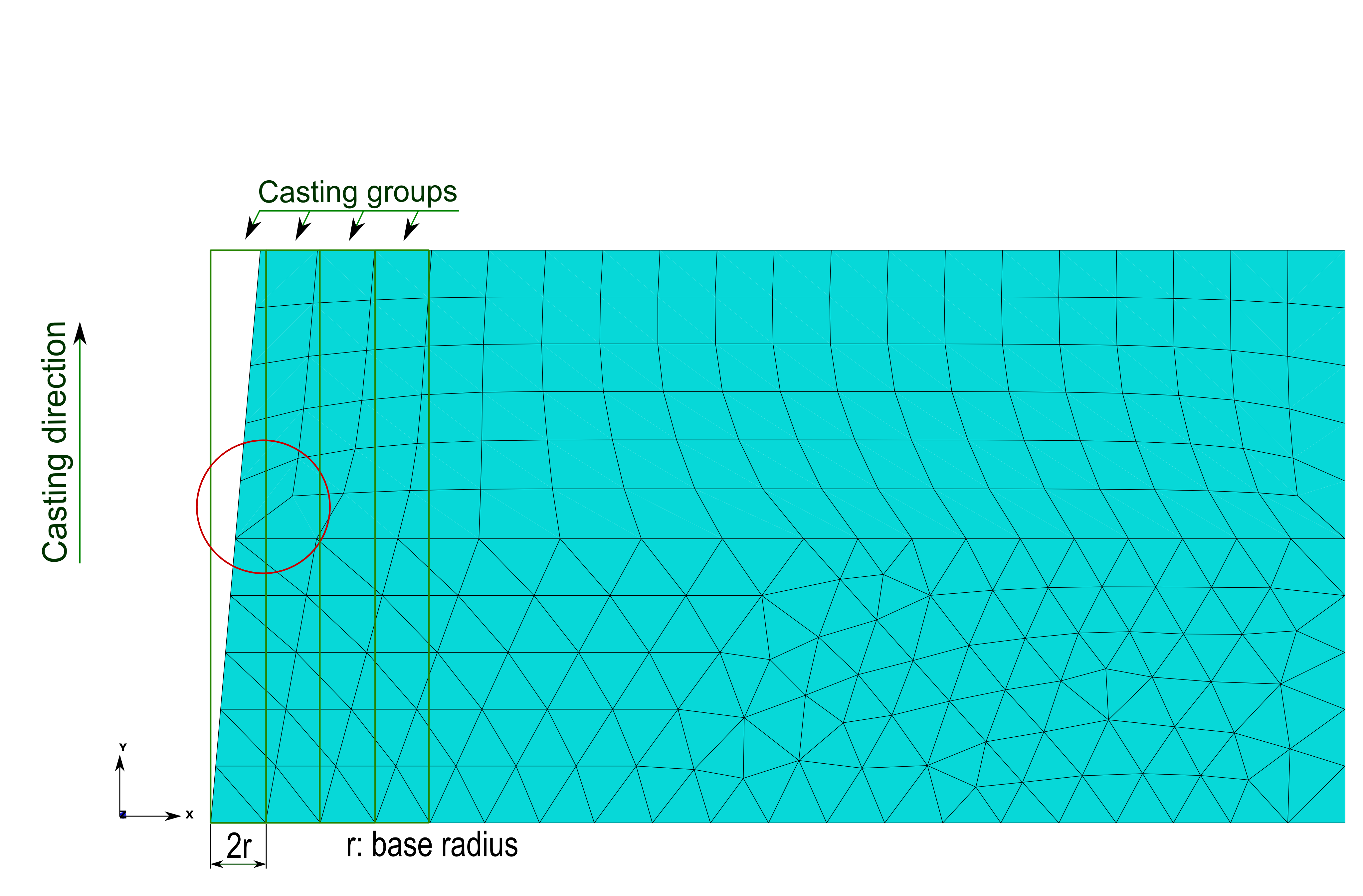

-

The elements are grouped into cells with a base radius (RADIUS)

which is automatically defined based on the average element size.

If the model has elements of very different sizes or the elements are not

aligned with the casting direction as exemplified in the next figure, it is

recommended to specify a superior value using the field RADIUS

of the same DVCON_TOPO block, considering that it should be

larger than approximately 50% of the element edge length.

| Important: The application of this approach with stresses as objective/constraints should be used with care when combined exclusively with objective/constraints which are not related with stiffness (such as mass), as the final design may present some intermediate densities. |