Combination of Manufacturing Restrictions | ||

| ||

Each geometrical restriction reduces the possibilities of the solution. Thus, it is necessary to add only the restrictions needed for solving the problem. It is still possible to find a solution if too many restrictions are defined, but the result will most probably be suboptimal compared to the optimal design. Therefore, the first step for the user is to perform an optimization without restrictions to obtain knowledge about the restrictions needed for the specific problem.

| Important: It is not possible to combine all manufacturing constraints at random. Be careful when combining the restrictions! |

The DVCON_TOPO constraints are processed in a fixed order (independent of the definition order in the parameter file):

- minimum member size

- symmetry

- casting restriction

- maximum member size

| Warning:

It is possible within this order that one constraint weakens the modification

of another. For example: A combination of reflection symmetry and a casting restriction defined by a pull direction which is not parallel to the reflection symmetry axis is questionable geometrically and the user is not allowed to specify such a restriction. |

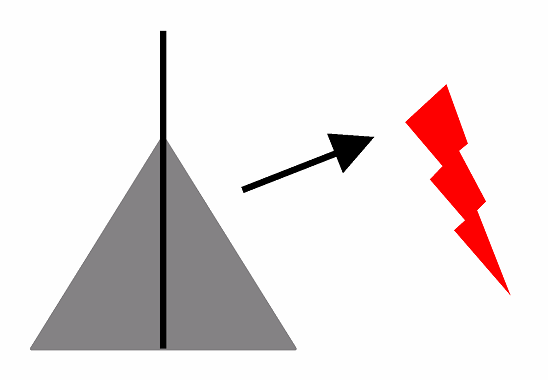

An Illegal combination of pull direction with reflection symmetry is shown in the following figure:

|

Possible Combinations of Manufacturing Restrictions

Examples for possible combinations are listed in the following:

- Reflection symmetry can be combined with a pull direction on the condition that the pull direction is perpendicular or parallel to the symmetry plane.

- Rotation symmetry and the definition of a pull direction: this combination is possible if the pull direction is parallel to the axis of rotation.

- Two reflection symmetries can be combined if the planes are perpendicular.

- Maximum member size control is not allowed for the controller based optimization.

- Minimum member size control and maximum member size control can be combined if the radius of the minimum member size is larger than the radius of the maximum member size (!). This can be done because the minimum member size control is processed before the maximum member size control. The optimizer creates thick supports that are broken up in the second step. Parallel double supports can often be seen with this combination. The choice of a radius for the maximum member size which is larger than the radius of the minimum member size does not influence the combination.

The following figure shows feasible combinations of pull directions and symmetry:

|