Start Tosca Structure.pre to define the optimization task.

Import the analysis model crank_shaft.ext (ext=inp, bdf, dat...).

If no groups are defined in the analysis input (e.g. for MSC Nastran® input) import the groups from the file groups.bdf which

can be found in the same directory as the analysis input. For more

details please refer to the Tosca Structure Getting Started manual.

Create the design variable area. The group DESIGN_ELEMENTS

contains the design elements.

Add a design response for the volume as a sum of all design elements

volumes.

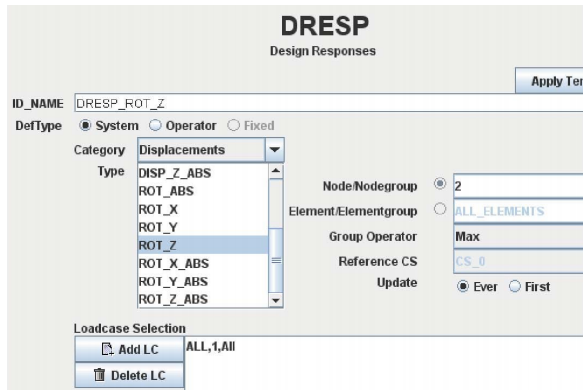

Create a design response for the rotational displacement on node 2 along

the z axis. Select the first load case to refer the design response to.

Create a second design response for rotational displacement on node 2

similar to the previous one. Select the rotation along the x axis and the

assign the second load case to the design response.

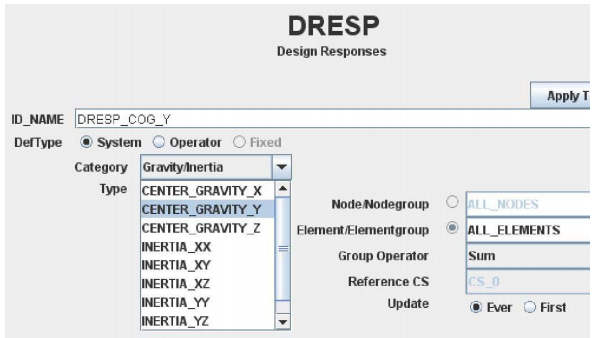

Create a design response for the y location of the center of gravity of the

whole model. Make sure to switch the Group Oper to

Sum.

Define the objective function to minimize the design volume.

Define constraints to maintain the torsional and bending stiffness as well as

to set the y location of the gravity center. In the first constraint set the

maximal value of 2.0e-6 for the z rotation of node 2. In the second

constraint set the maximal value of 1.2e-6 for the x rotation of node 2. In

the third constraint set a maximal value of -18 for the y coordinate of the

center of gravity. All constraint types should be less or equal and the

magnitude values should be set to ABS.

Compose the optimization task (OPTIMIZE) and select the predefined

definitions. Choose the TOPO_SENSITIVITY optimization strategy. Make

sure to reference all defined CONSTRAINT items in the OPTIMIZE

command

Define some additional optimization parameters via the OPT_PARAM

command. Increase the initial density from 0.5 to 0.9.

Start the complete SIMULIA Tosca Structure optimization using the start option type

= all.

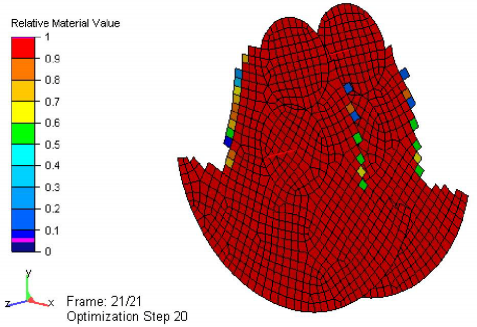

The optimization is finished after approx. 20 design cycles. The

results in form of material distribution

are as follows: