Choose a TOPOLOGY_OPTIMIZATION_SENSITIVITY task and create the model link.

Create the design area of all elements and fix the

frozen_elements element group.

Define a demold restriction on all elements using a middle plane

through the point with coordinates 0, 0, -20 and the global

positive z-axis as pull direction.

Set up the objective function to minimize the crane hook volume.

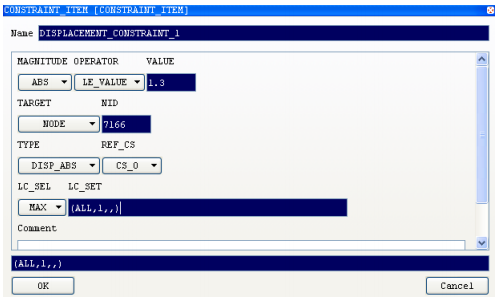

To define a displacement constraint, select in the task manager PRE_PROCESSING

| CONSTRAINTS | NEW | DISPLACEMENT_CONSTRAINT.

In the CONSTRAINT item, switch the MAGNITUDE to ABS and enter the

maximal value for the displacement in 1.3. Switch the TARGET to NODE

and

specify the node number 7166. Specify the load case number 1 for

this constraint:

Create an identical displacement constraint for load case number 2.

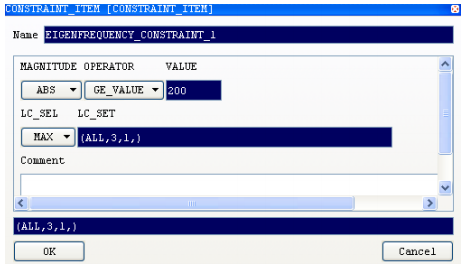

To define a displacement constraint, select in the task

manager PRE_PROCESSING

| CONSTRAINTS | NEW | EIGENFREQUENCY_CONSTRAINT.

In the CONSTRAINT item, switch the MAGNITUDE to ABS, select a

GE_VALUE to and enter the minimum value for the first

eigenfrequency, 200. Specify the load case number 3 and

additionally the substep number 1 for this

constraint. In this case the selected substep

number will refer to the eigenfrequency with the same order number: