Uniaxial and multiaxial stress and strain | ||

| ||

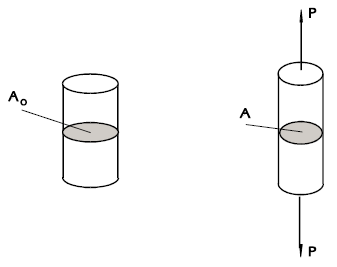

The conventional test specimen for materials’ testing is shown in Figure 7.4.

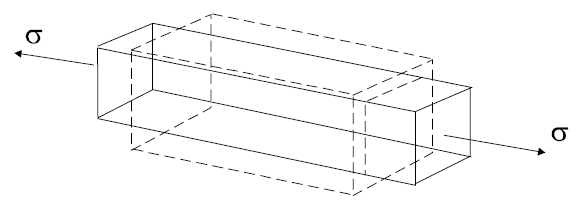

If this is re-drawn as a rectangular section (Figure 7.5) then it can be seen that as the specimen is extended in the longitudinal direction, it contracts in the two perpendicular directions. The fact that the specimen is free to contract means that no stress is produced on these planes, and so the specimen is in a state of uniaxial stress. There are strains in all three directions, and so the strains are multiaxial.

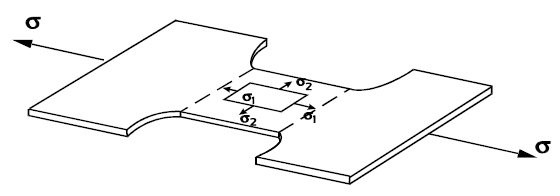

If the specimen is changed to one which is wide but still thin (Figure 7.6) the specimen is not free to contract in width (except at the very edge) because it is restrained by the lower-stressed material at the ends of the specimen, and so a stress is produced in the transverse direction. The specimen is therefore in a state of biaxial stress. As there is no stress in the out-of-plane direction, this condition is one of plane stress. There is an out-of-plane strain, so this is not a plane strain condition.

Fatigue cracks usually initiate from the surface of a component, where there is no out-of-plane stress. Much multiaxial fatigue research is therefore the study of fatigue plane stress biaxial stresses.